- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-09 Origin: Site

Have you ever wondered how softgel capsules are made? These capsules are easy to swallow and offer precise dosing. They are highly valued in pharmaceuticals and nutraceuticals.

In this article, we’ll explain the detailed process of making softgels. You’ll learn about each key stage and how modern technology ensures quality.

By the end, you’ll understand how machines help produce consistent, high-quality capsules. Learn more about our products at Sinagel.

Gelatin is the primary component used to form the shell of the softgel capsule. Depending on the product, the fill material can vary—from oils, such as fish oil, to pharmaceutical ingredients in suspension. The Softgel machine ensures that the fill material is precisely injected into the gelatin ribbons to create consistent, accurate capsules.

The choice of fill material is critical for both efficacy and stability. The Softgel machine adjusts its settings to handle a range of viscosities, ensuring smooth material flow and uniform encapsulation. The process starts with ensuring that the viscosity of the fill material is ideal for smooth and efficient encapsulation.

Plasticizers such as glycerin or sorbitol are added to the gelatin mixture to enhance its flexibility and prevent brittleness. These additives are mixed thoroughly to ensure smooth integration into the gelatin. The Softgel machine is designed to handle this mixture precisely, maintaining the balance required for optimal performance.

Other additives like colorants and stabilizers are also included to enhance the appearance of the capsules and ensure stability during storage. The machine's ability to mix these additives consistently ensures that each batch of capsules meets the same high standards.

Viscosity is a key factor in the encapsulation process, as it affects how easily the fill material flows into the gelatin ribbons. If the material is too thick or too thin, it can lead to issues such as uneven filling or improper encapsulation. Consistency and homogeneity of the mixture are crucial to achieving a uniform capsule size and consistent dosage in every softgel.、

Component | Function |

Gelatin Melting Tank | Heats and mixes gelatin to form a gel-like substance for ribbons |

Material Feeding Pump | Pumps fill material into the gelatin ribbons with precise dosing |

Injection Wedge | Injects the fill material between gelatin ribbons to form a pocket |

Cooling Drum | Cools the gelatin ribbons, ensuring proper thickness and solidification |

Drying System | Removes excess moisture from the softgel capsules to stabilize them |

Gelatin forms the outer shell, which protects the active ingredients and makes the capsules easy to ingest. The gelatin mixture is heated and dissolved in water, creating a gel-like substance. This gelatin solution is spread onto rotating drums inside the Softgel machine, where it is formed into thin ribbons.

The gelatin must be uniform and strong enough to encapsulate the fill material, but also flexible enough to prevent breakage during handling or consumption.

The gelatin mixture is carefully spread onto rotating drums, where it forms thin, uniform ribbons. The Softgel machine controls the speed and temperature of the drums to ensure the ribbons are consistent in thickness, which is crucial for maintaining capsule integrity. Uniform thickness is essential to ensure that the softgels are of the same size and strength.

Once the ribbons are formed, they are cooled and solidified using fans. The cooling process is essential to ensure that the ribbons maintain the correct thickness and consistency before they are used to create capsules. The machine carefully regulates the cooling process to prevent the ribbons from becoming too rigid or too soft.

At this stage, the fill material is injected into the gelatin ribbons. A wedge system is used to feed the material between two ribbons of gelatin, creating a pocket for the fill. The material is injected with precision to ensure each capsule is filled with the correct dosage. Accurate feeding and filling systems are vital to maintaining consistency across all capsules.

The filling system must be carefully calibrated to ensure uniformity in every capsule, which is essential for maintaining the integrity and effectiveness of the product.

As the gelatin ribbons are pressed together, they form a pocket that will hold the fill material. This pocket is sealed tightly to ensure that the material does not leak out. The sealing process is carried out under controlled conditions to ensure each capsule is securely formed and the fill material stays intact inside the gelatin shell.

Ensuring uniform fill weight across all capsules is essential for consistency. The Softgel machine ensures that the right amount of fill material is injected into each capsule. This consistency is vital for ensuring that every capsule delivers the intended dosage of active ingredients.

Once the fill material is injected into the gelatin ribbons, the capsules are sealed and cut into shape using rotary dies. The sealing process ensures that the capsules are properly sealed to prevent leakage and that they are shaped consistently. Proper sealing is essential to the overall quality of the capsule, ensuring that it performs as intended.

The rotary die system works in tandem with the encapsulation process, guaranteeing that each capsule is formed, sealed, and cut to the required specifications.

After sealing, the softgel capsules are cut into their final size and shape. This ensures consistency in appearance and guarantees that the capsules meet size and weight standards. Uniformity in size is essential for ensuring that the correct dosage is delivered to the consumer.

Once the capsules are sealed and cut, they are subjected to tumble drying to remove excess moisture. The Softgel machine ensures that the drying conditions are optimal, preventing the capsules from becoming too dry or too moist.

The drying process is crucial to ensure the capsules maintain their flexibility and structural integrity.

After tumble drying, the capsules undergo tray drying to further reduce moisture content and stabilize the capsules. This step helps prevent the capsules from becoming brittle or too soft. The drying process is carefully monitored to ensure that the capsules retain their flexibility without compromising their strength.

Proper drying conditions are essential for achieving the right moisture content. The Softgel machine ensures that the drying temperature and humidity are closely monitored throughout the process to ensure that the softgels are stable and of the highest quality.

Throughout the softgel production process, the thickness and uniformity of the gelatin ribbons are constantly checked. Inconsistent ribbons can lead to defective capsules, which is why this step is crucial for maintaining quality.

The Softgel machine ensures that the fill weight is accurate and that the seals are strong and leak-proof. These checks are essential for ensuring that each capsule performs as expected.

After production, softgel capsules undergo final testing to ensure they meet dissolution and stability standards. This testing is crucial to confirm that the capsules perform as expected once ingested, providing the intended benefits.

Quality Control Check | Purpose |

Ribbon Thickness | Ensures uniform shell thickness and consistency |

Fill Weight Accuracy | Verifies that each capsule contains the correct dosage |

Seal Integrity | Confirms that the capsules are securely sealed to prevent leakage |

Dissolution Rate | Ensures that capsules dissolve correctly and release active ingredients effectively |

As consumer demand for vegan and halal products grows, plant-based gelatin alternatives are being incorporated into the production process. These alternatives provide the same functionality as traditional gelatin, catering to a broader range of consumers without compromising on capsule quality.

Innovative coating technologies, such as enteric and delayed-release coatings, have been integrated into the softgel production process. These coatings improve the bioavailability of certain active ingredients, ensuring that they are released at the right time in the digestive system.

Automation continues to improve the efficiency of softgel production. The Softgel machine has evolved to handle more tasks with less human intervention, increasing speed and reducing labor costs, making softgel manufacturing more cost-effective and scalable.

Making softgels is a detailed process involving multiple precise steps. Each stage, from gelatin ribbon formation to drying, requires specialized equipment to ensure consistency and quality. With advancements in technology, the process has become more efficient, meeting the rising demands of the pharmaceutical and nutraceutical industries. At Sinagel, our products provide reliable and high-quality solutions for softgel production, ensuring optimal results and meeting diverse consumer needs.

A: The process involves preparing gelatin, filling materials, injecting them into ribbons, sealing, and drying the capsules. Each step ensures consistent quality and dosage.

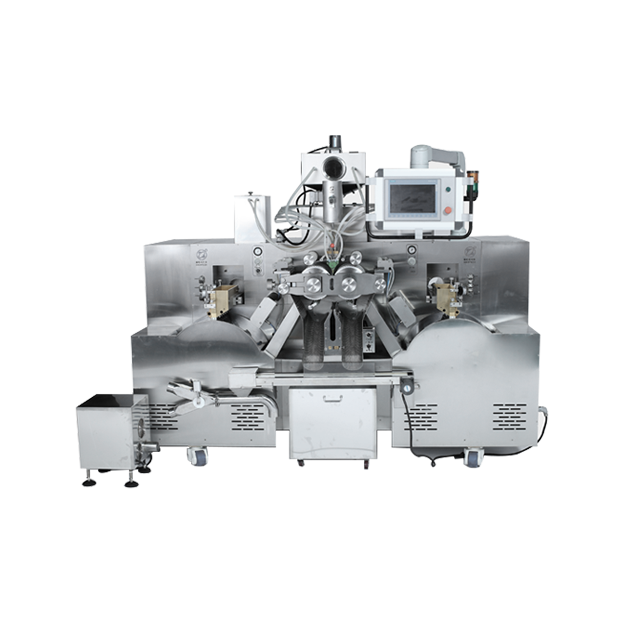

A: A softgel machine creates the gelatin ribbons, injects the fill material, seals, and cuts the capsules with high precision to ensure uniformity and quality.

A: Viscosity ensures smooth flow of the fill material into the gelatin ribbons, helping achieve consistent dosage and preventing defects during encapsulation.

A: Softgel capsules offer precise dosing, improved bioavailability, and easy ingestion, making them ideal for pharmaceutical and nutraceutical products.