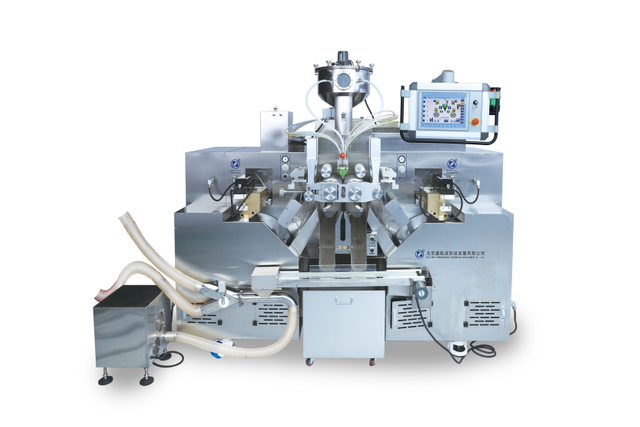

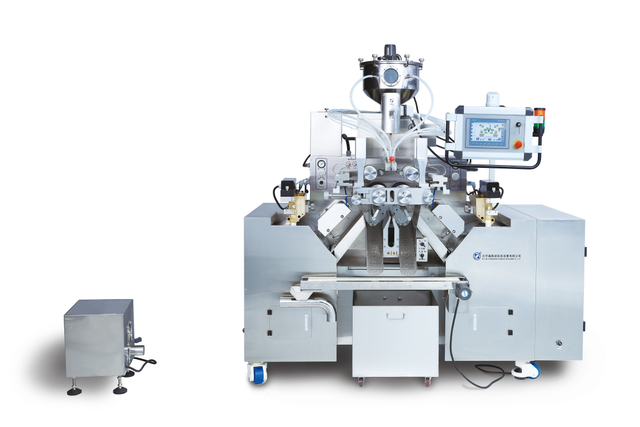

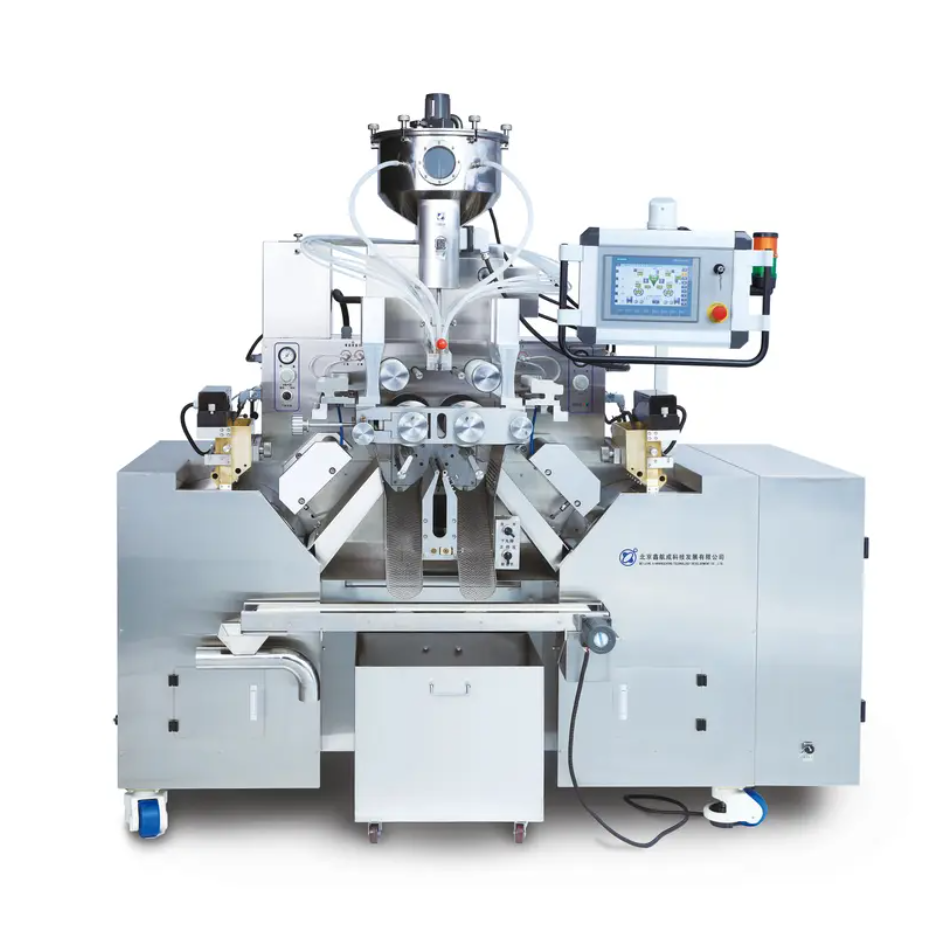

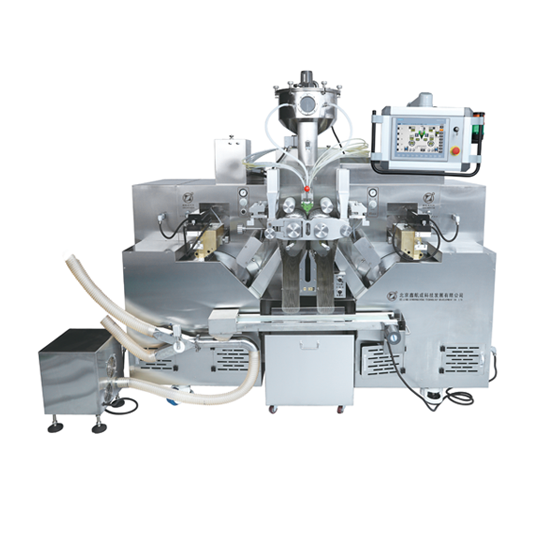

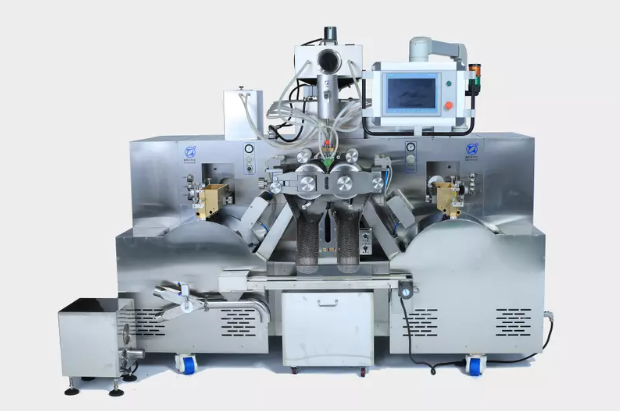

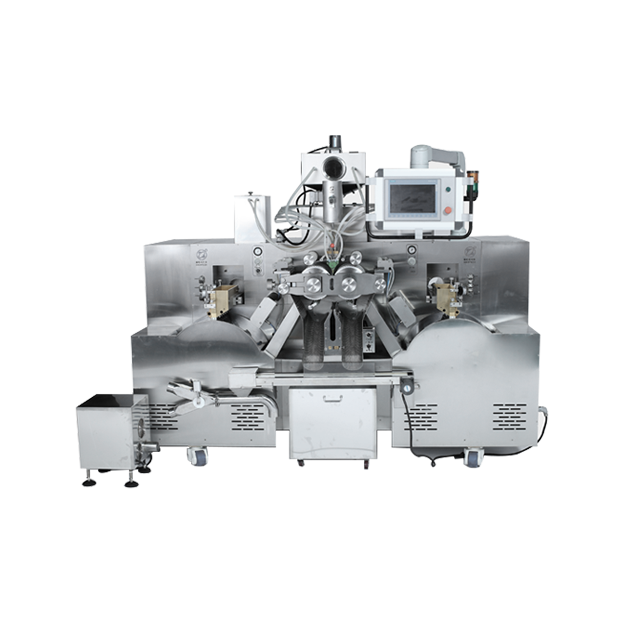

Automatic Fish Oil Filling Machine for Softgel Production

Welcome to learn about our Fish Oil Filling Machine! It comes with nitrogen protection (reduces oil oxidation), low-temperature adaptability—great for softgel production. Feel free to ask for more details!

Product Overview

Core Technology: Address Key Pain Points in Fish Oil Filling

Adopts nitrogen-protected filling technology; it injects nitrogen first via a three-way pipe to isolate oxygen, reducing fish oil oxidation. It is also equipped with a Z-axis linear module to lift the pipe synchronously during filling, eliminating waiting time for extraction and improving filling efficiency. Features a piston-based design; the bottom piston pushes liquid for delivery, which effectively adapts to the high viscosity of fish oil in low-temperature environments and avoids filling blockages or inaccurate dosages.

Stable Performance: Meet Production Needs & Compliance Standards

Controllable capacity and specifications: Key components like the die roller and cooling drum have fixed parameters, supporting filling of all capsule sizes from #1.5 OV to #32 OV or #4 OB to #20 OB. Made of SS304/SS316L stainless steel and certified with dual CE certifications, meeting industry standards for pharmaceuticals and health supplements. It also comes with a 1-year official warranty to ensure long-term stable operation of the equipment.

Practical Design: Reduce Operation & Maintenance Costs

Open equipment structure: key components are easy to disassemble, and it is equipped with intuitive touch control, reducing daily maintenance time. Some components are compatible with cleaning systems, lowering cleaning difficulty. Complete supporting equipment included: rotary drum dryer, PPE capsule trays, air compressor, and gelatin melting tank. No additional purchases are needed to quickly set up small-to-medium production lines.

Product Advantage

Designed specifically for fish oil filling needs, our machine delivers 4 critical advantages that enhance product quality, operational stability, compliance, and cost-efficiency.

Oxidation Prevention & Filling Efficiency: Safeguard Product Quality While Boosting Speed

Low-Temperature Adaptability: Ensure Stable Operation in Challenging Conditions

Compliance & Durability: Meet Industry Standards for Long-Term Reliability

Cost-Effective & User-Friendly: Lower Operational Burden for Businesses

Technical Specifications

Below are the detailed Technical Specifications of our Fish Oil Filling Machine, covering core performance, structural details, and supporting equipment parameters to help you fully understand its operational capabilities.

Core Machine

Structural & Material

Supporting Equipment

Application

Fish Oil Softgel Production Lines

This machine is specifically engineered for the automated filling of fish oil softgels—a core need in the health supplement and pharmaceutical industries. It seamlessly integrates into small-to-medium production lines, handling the full filling process while addressing fish oil’s unique characteristics: its nitrogen protection system prevents oxidation (critical for preserving omega-3 active ingredients), and its piston-driven design ensures smooth filling even when fish oil thickens in low-temperature workshops. Compatibility with capsule sizes from #1.5 OV to #32 OV or #4 OB to #20 OB, it meets the production demands of brands focused on fish oil supplements, from small-batch premium products to mid-scale mass production.

Multi-Dosage & Cross-Industry Adaptation

Beyond fish oil softgels, the machine offers flexible adaptation for other capsule-based formulations, making it a versatile asset for businesses with diverse product lines. It can efficiently fill capsules containing powders (e.g., vitamin blends), granules (e.g., herbal extracts), or pills (e.g., mineral supplements)—no need for extensive component replacements. This adaptability allows it to serve cross-industry needs: in the pharmaceutical sector, it supports small-batch production of prescription capsule medications; in the health food industry, it caters to multi-nutrient capsule products. Additionally, its compact size and complete supporting equipment (dryers, trays, melting tanks) make it easy to integrate into existing workshops or new production setups, reducing the need for additional infrastructure investment.

Why Choose Us

Choosing the right soft capsule equipment provider is critical to your production success, and we deliver value through 4 key strengths that have made us a leading name in the industry.

20+ Years Industry Expertise & Pioneering Innovation

Founded in 1998, we have specialized in soft capsule equipment for 20+ years, integrating R&D, production, sales, and service into a full-service model. Leveraging unique aerospace technology advantages, we’ve achieved multiple "industry firsts"—including China’s first fully automatic high-speed soft capsule machine, the first PLC-controlled automatic soft capsule machine, and the first fully explosion-proof soft capsule cleaning machine. These innovations have filled domestic gaps, led industry development, and solidified our position as a leading enterprise in the soft capsule equipment sector.

Global Certification & International Market Recognition

Our equipment meets strict global standards, holding CE certification to ensure compliance with pharmaceutical and health supplement industry requirements worldwide. For years, our products have been exported to over 100 countries and regions across Europe and the Americas, including key markets like the United States, Canada, Russia, and Malaysia. This international footprint not only validates the quality of our equipment but also makes us a trusted, well-known provider of soft capsule and drop-pill technology on the global stage.

Customer-Centric Service & Trusted Partnerships

We adhere to a "customer-first" philosophy, viewing customers’ good reputation as the core driver of our development. Our commitment extends beyond delivering high-quality equipment—we provide end-to-end support to help customers achieve business goals and enhance market competitiveness. This focus on service has earned us recognition from leading brands (such as strategic partnership certifications and after-sales service awards) and built long-term, trusted relationships with clients across the pharmaceutical and health food industries.

Social Responsibility & Sustainable Development

We take our corporate responsibility seriously, with actions covering three key areas: Sustainable Production: We use eco-friendly technologies and materials, optimize processes to improve resource efficiency, and reduce environmental impact through green manufacturing practices. Employee Care: We prioritize staff career development, offering fair opportunities and a positive work environment to foster mutual growth between employees and the company. Social Contribution: We actively participate in public welfare initiatives, supporting education and environmental protection to give back to society and promote harmony. Additionally, we maintain strict safety and quality management systems, ensuring all products meet the highest safety standards from raw material procurement to delivery.

Subscribe To Our Newsletter

Stay updated on the latest soft capsule equipment innovations, industry insights, and exclusive offers—subscribe to our newsletter for timely, valuable updates tailored to your production needs.

FAQ

Do your soft capsule equipment meet international standards?

A: Yes. All our equipment has passed the CE certification, which complies with strict quality and safety requirements for pharmaceutical and health supplement equipment. To date, our products have been exported to over 100 countries and regions (including the U.S., Canada, Russia, Malaysia, etc.), fully adapting to the regulatory needs of different global markets.

What makes your soft capsule equipment stand out from competitors?

What kind of support can customers get after purchasing your equipment?

Does your company adopt eco-friendly measures in equipment production?

Can your soft capsule equipment be used for products other than standard soft capsules?

Related Blogs

How Does A Softgel Machine Work?

What Is The Process of Making Softgels?

What Is The Working Principle of Soft Capsule Encpasulator?

Keep in touch with us

Whether you have questions about soft capsule equipment, need support for your production line, or want to discuss partnership opportunities—we’re here to connect. Keep in touch with us for personalized assistance tailored to your needs.

Mob: +86-13601283135

E-mail: chinasoftgel@outlook.com

English

English