- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

YWJ300-III

Sinagel, a leading manufacturer and engineering expert in the field, presents the Automatic Intelligent Gelatin Melting System, a revolutionary solution designed for high-efficiency softgel preparation lines. This advanced equipment replaces traditional manual gelatin preparation processes, significantly reducing operator labor intensity while dramatically improving batch uniformity and production throughput.

The core of the system lies in an SS316L jacketed melting tank with superior insulation performance, ensuring stable temperature control during the gelatin melting process. It automates the entire workflow, including powder addition, heating, mixing, and degassing, effectively solving the problem of quality drift caused by manual dosing and vacuum defoaming. Equipped with a PLC + HMI control system, the system supports recipe management, batch record tracking, and remote assistance, fully meeting the strict documentation requirements of pharmaceutical and food production plants. Available in two models, ZHJG-600 (600 L) and ZHJG-800 (800 L), it is widely applicable to various industries that require gelatin melting and softgel production.

The system realizes full-process automation through a PLC + HMI control system, integrating water dosing, powder feeding, glycerin and color addition, weighing, mixing, heating, vacuum, and cleaning functions into one operation interface. Each production step is precisely controlled by the PLC, minimizing manual intervention, reducing human error, and ensuring stable and consistent output quality.

Users can save various process parameters such as material ratios, heating temperatures, and holding times as recipes. During production, one-click recipe recall is available, and the closed-loop heating system maintains stable viscosity, moisture, and Bloom strength of the gelatin slurry. This ensures that product quality is consistent across different shifts and batches, avoiding batch-to-batch differences.

Adopting a sanitary design concept, all parts in contact with materials use SS316L stainless steel, paired with hygienic valves and quick clamps. The optional CIP (Clean-in-Place) system enables automated cleaning of tanks, pipelines, and pumps, shortening changeover time between different formulas and reducing the risk of cross-contamination. The smooth surface of the equipment further facilitates cleaning and maintenance.

It offers three heating methods: electric, steam, and thermal oil, with customizable ramp rates and holding points to prevent overheating of the gelatin slurry. The insulated jacket design reduces heat loss, while the variable-speed scraper mixer minimizes shear force, protecting the gel network structure. This not only improves the quality of the gelatin slurry but also reduces energy consumption and drying rework rates.

The system is equipped with sanitary lobe or diaphragm pumps and heat-traced piping, and its ports are perfectly matched with common softgel encapsulators for easy connection without complex retrofitting. Enterprises can choose between ZHJG-600 and ZHJG-800 models according to their production scale, and achieve capacity expansion as demand grows.

The Automatic Intelligent Gelatin Melting System is a versatile pharmaceutical gelatin melting machine suitable for multiple industries:

Pharmaceuticals: Production of various softgel medicines, ensuring the stability and uniformity of drug-loaded capsules.

Nutraceuticals: Preparation of health supplement softgels such as fish oil, vitamin, and probiotic capsules.

Food Industry: Manufacturing of edible softgel products like candy capsules and functional food capsules.

Cosmetics: Production of cosmetic softgels such as facial oil capsules and hair care oil capsules.

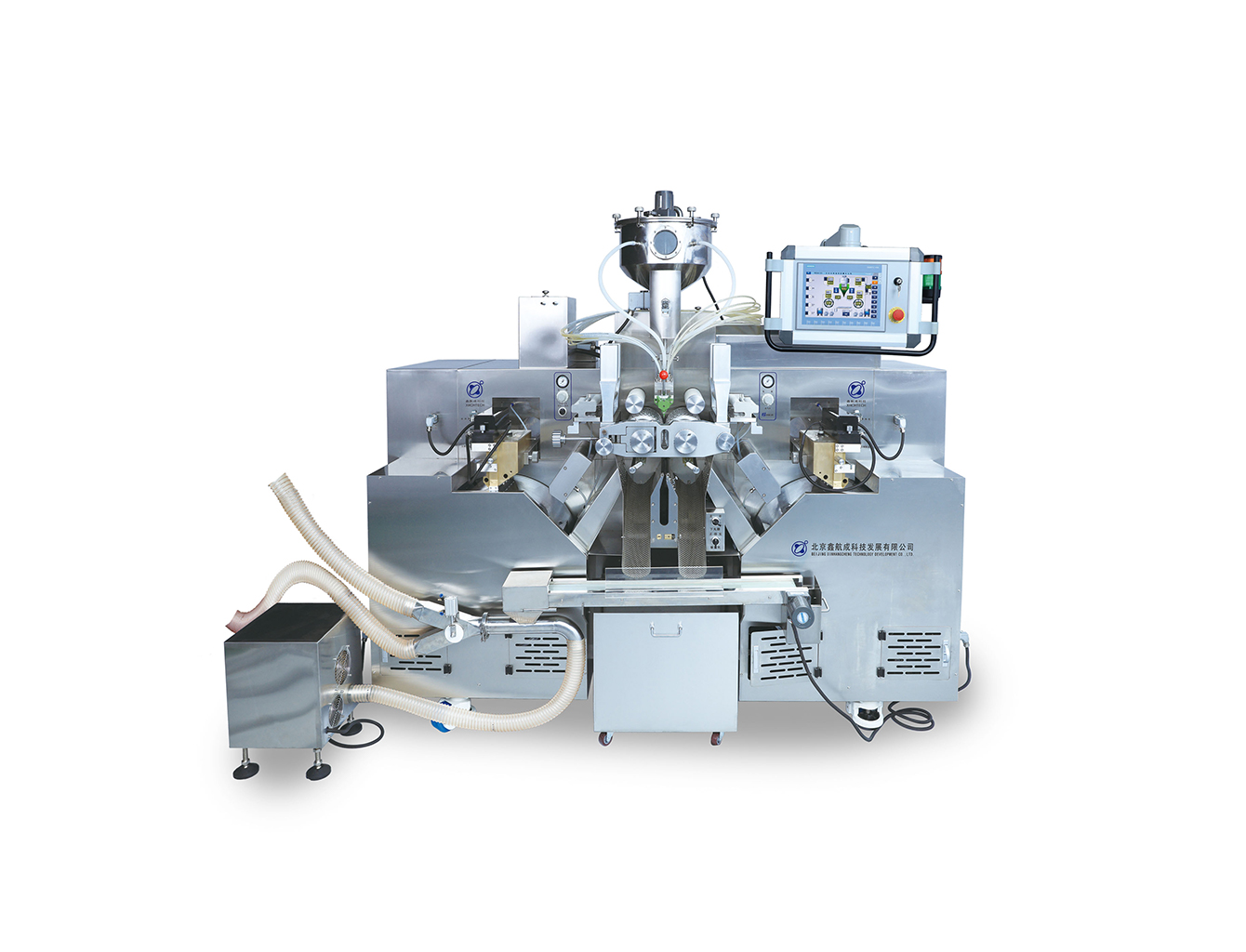

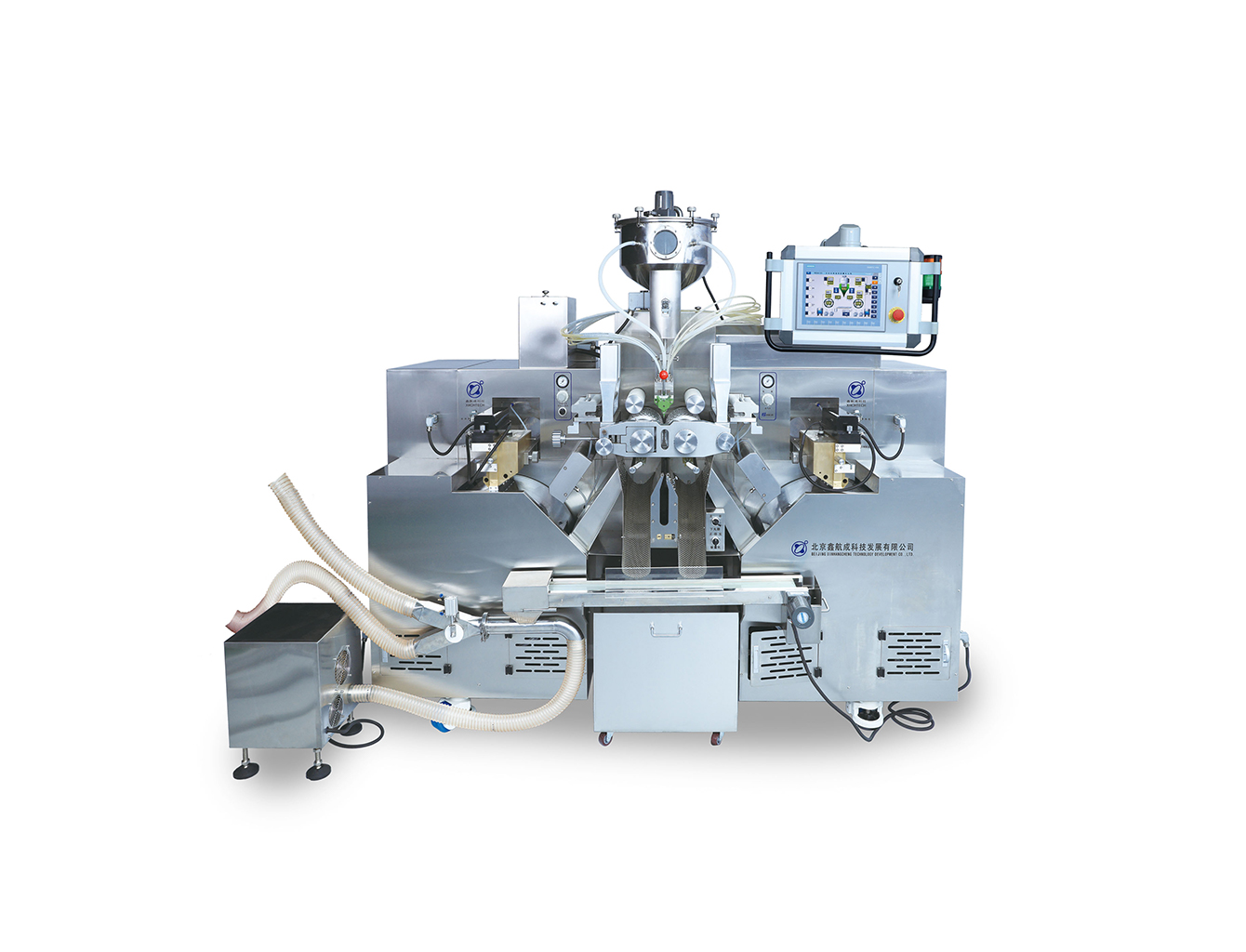

Product Name | Automatic Servo Capsule Production Machine |

Model | YWJ300-III |

Mold Roll Size | Φ200 × 300 mm |

Cavities (8# OV) | 799 |

Die Roll Speed | 0–7 rpm, servo controlled |

Single Plunger Fill Volume | 0–2 ml, continuous adjustment |

Number of Plungers | 24 |

Filling Accuracy | ±0.5% (oil) / ±1.5% (suspension) |

Output (8# OV) | 287,640 capsules/hour at 6 rpm |

Total Power | 16 kW |

Power Supply | 380 V, three-phase |

Weight | 1600 kg |

Dimensions (L × W × H) | 2400 × 1250 × 2100 mm |

We provide matched ports, heated and filtered transfer pipelines, and PLC/HMI interlock signals. OEM adapters and turnkey commissioning services are available to achieve seamless connection without major retrofitting of your production line.

The closed-loop heating system with recipe control manages ramp rates and holding points, while inline sensors real-time monitor temperature and viscosity. The integrated vacuum degassing module removes bubbles from the slurry, ensuring uniform quality of softgel shells and stable encapsulation processes.

The CIP-equipped system performs automated rinsing and washing of tanks, pipelines, and pumps. We provide standard operating procedures (SOPs), visual inspection guidelines, and residue testing methods to help you meet GMP audit requirements.

Sinagel, a leading manufacturer and engineering expert in the field, presents the Automatic Intelligent Gelatin Melting System, a revolutionary solution designed for high-efficiency softgel preparation lines. This advanced equipment replaces traditional manual gelatin preparation processes, significantly reducing operator labor intensity while dramatically improving batch uniformity and production throughput.

The core of the system lies in an SS316L jacketed melting tank with superior insulation performance, ensuring stable temperature control during the gelatin melting process. It automates the entire workflow, including powder addition, heating, mixing, and degassing, effectively solving the problem of quality drift caused by manual dosing and vacuum defoaming. Equipped with a PLC + HMI control system, the system supports recipe management, batch record tracking, and remote assistance, fully meeting the strict documentation requirements of pharmaceutical and food production plants. Available in two models, ZHJG-600 (600 L) and ZHJG-800 (800 L), it is widely applicable to various industries that require gelatin melting and softgel production.

The system realizes full-process automation through a PLC + HMI control system, integrating water dosing, powder feeding, glycerin and color addition, weighing, mixing, heating, vacuum, and cleaning functions into one operation interface. Each production step is precisely controlled by the PLC, minimizing manual intervention, reducing human error, and ensuring stable and consistent output quality.

Users can save various process parameters such as material ratios, heating temperatures, and holding times as recipes. During production, one-click recipe recall is available, and the closed-loop heating system maintains stable viscosity, moisture, and Bloom strength of the gelatin slurry. This ensures that product quality is consistent across different shifts and batches, avoiding batch-to-batch differences.

Adopting a sanitary design concept, all parts in contact with materials use SS316L stainless steel, paired with hygienic valves and quick clamps. The optional CIP (Clean-in-Place) system enables automated cleaning of tanks, pipelines, and pumps, shortening changeover time between different formulas and reducing the risk of cross-contamination. The smooth surface of the equipment further facilitates cleaning and maintenance.

It offers three heating methods: electric, steam, and thermal oil, with customizable ramp rates and holding points to prevent overheating of the gelatin slurry. The insulated jacket design reduces heat loss, while the variable-speed scraper mixer minimizes shear force, protecting the gel network structure. This not only improves the quality of the gelatin slurry but also reduces energy consumption and drying rework rates.

The system is equipped with sanitary lobe or diaphragm pumps and heat-traced piping, and its ports are perfectly matched with common softgel encapsulators for easy connection without complex retrofitting. Enterprises can choose between ZHJG-600 and ZHJG-800 models according to their production scale, and achieve capacity expansion as demand grows.

The Automatic Intelligent Gelatin Melting System is a versatile pharmaceutical gelatin melting machine suitable for multiple industries:

Pharmaceuticals: Production of various softgel medicines, ensuring the stability and uniformity of drug-loaded capsules.

Nutraceuticals: Preparation of health supplement softgels such as fish oil, vitamin, and probiotic capsules.

Food Industry: Manufacturing of edible softgel products like candy capsules and functional food capsules.

Cosmetics: Production of cosmetic softgels such as facial oil capsules and hair care oil capsules.

Product Name | Automatic Servo Capsule Production Machine |

Model | YWJ300-III |

Mold Roll Size | Φ200 × 300 mm |

Cavities (8# OV) | 799 |

Die Roll Speed | 0–7 rpm, servo controlled |

Single Plunger Fill Volume | 0–2 ml, continuous adjustment |

Number of Plungers | 24 |

Filling Accuracy | ±0.5% (oil) / ±1.5% (suspension) |

Output (8# OV) | 287,640 capsules/hour at 6 rpm |

Total Power | 16 kW |

Power Supply | 380 V, three-phase |

Weight | 1600 kg |

Dimensions (L × W × H) | 2400 × 1250 × 2100 mm |

We provide matched ports, heated and filtered transfer pipelines, and PLC/HMI interlock signals. OEM adapters and turnkey commissioning services are available to achieve seamless connection without major retrofitting of your production line.

The closed-loop heating system with recipe control manages ramp rates and holding points, while inline sensors real-time monitor temperature and viscosity. The integrated vacuum degassing module removes bubbles from the slurry, ensuring uniform quality of softgel shells and stable encapsulation processes.

The CIP-equipped system performs automated rinsing and washing of tanks, pipelines, and pumps. We provide standard operating procedures (SOPs), visual inspection guidelines, and residue testing methods to help you meet GMP audit requirements.

The machine is mainly composed of a vibrator assembly, disc distribution system, chain drive part, display screen, electric control box assembly, camera box assembly, scrap box car, charging device, visual system, electronic control system, ejection system, etc. This sophisticated setup makes it an ideal soft gel capsule machine for modern production needs.