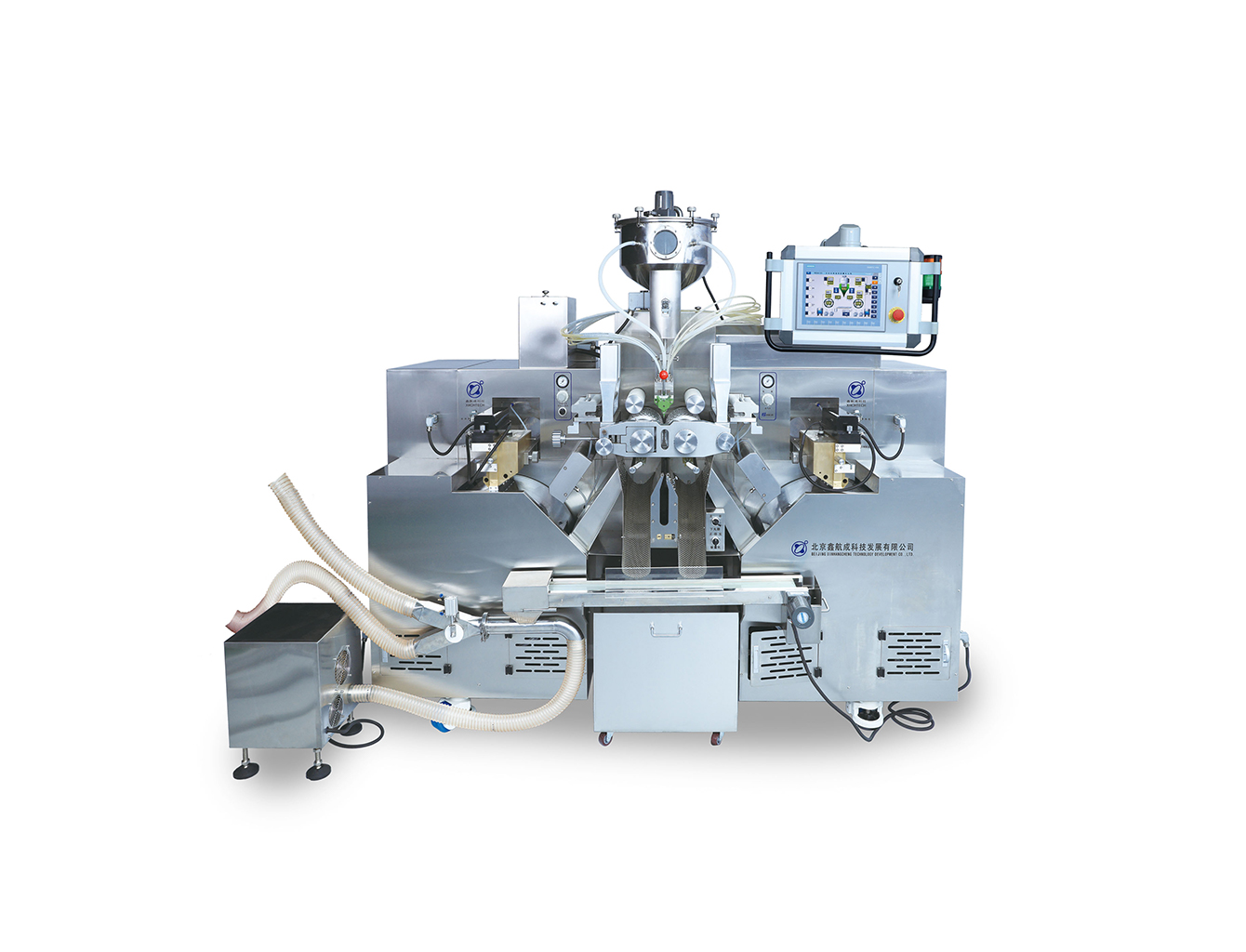

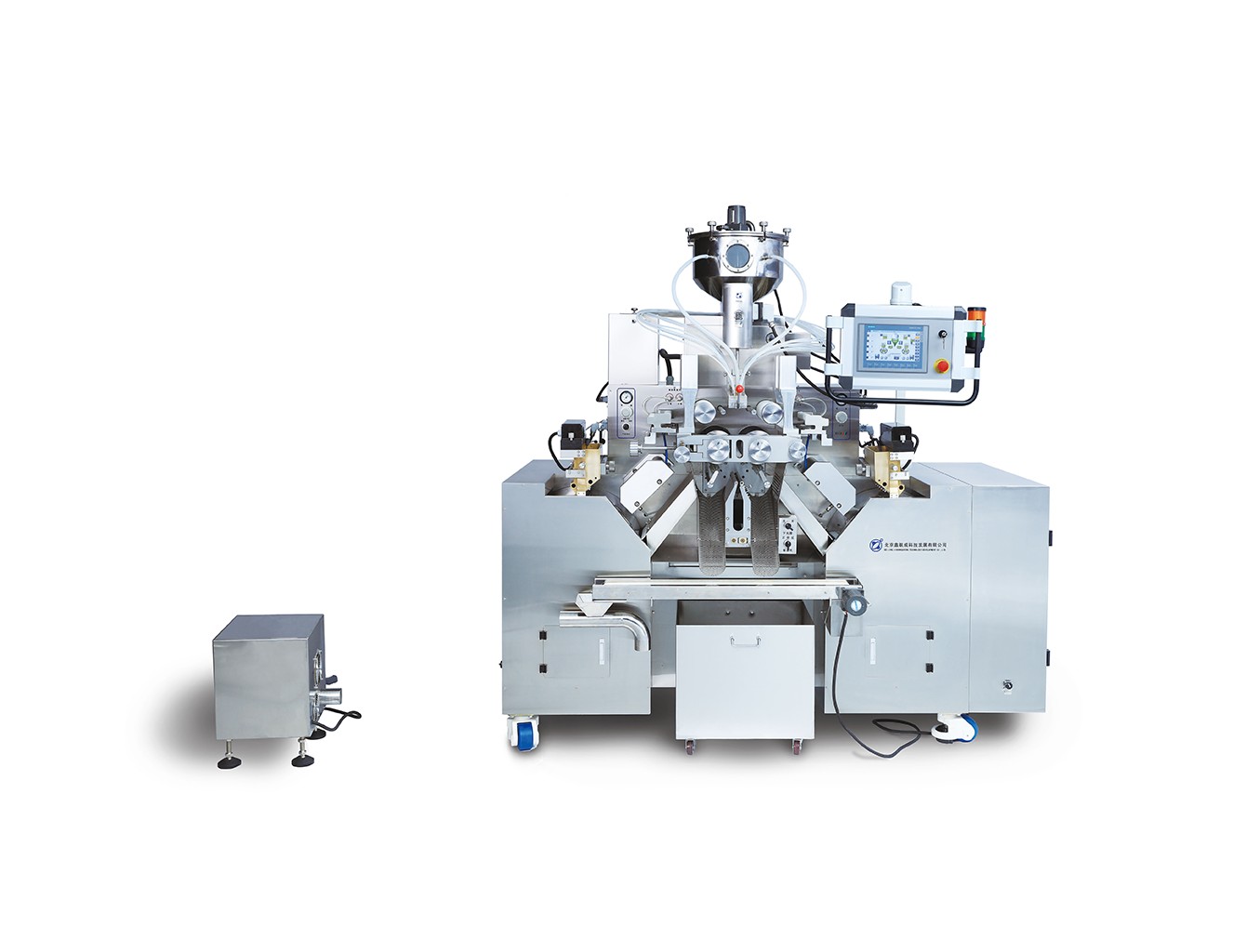

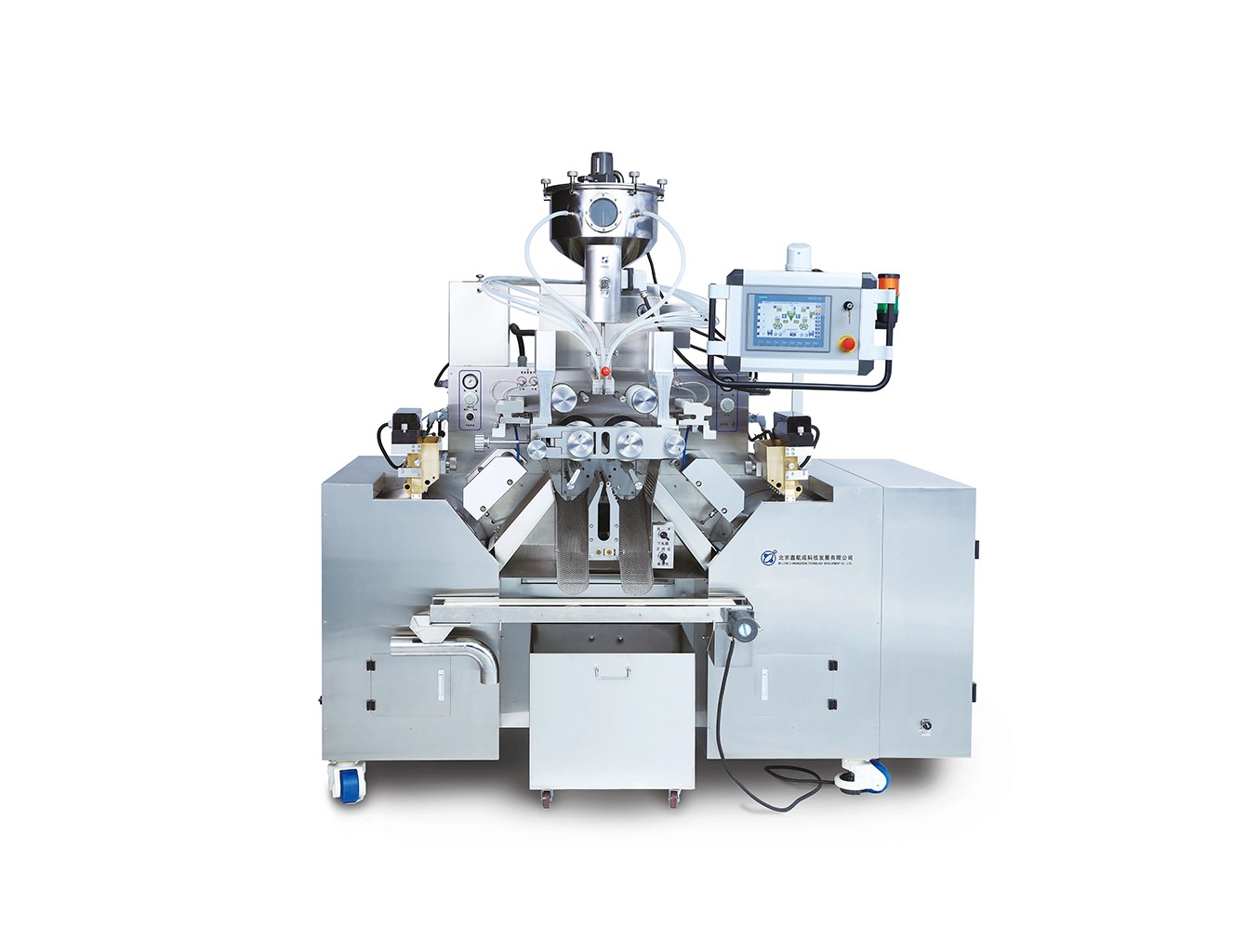

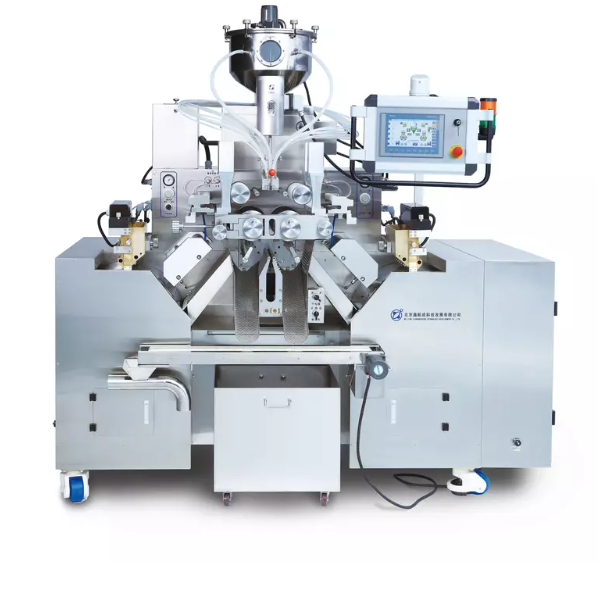

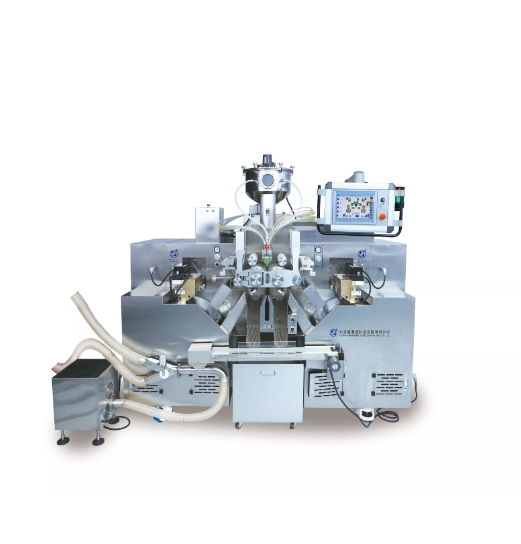

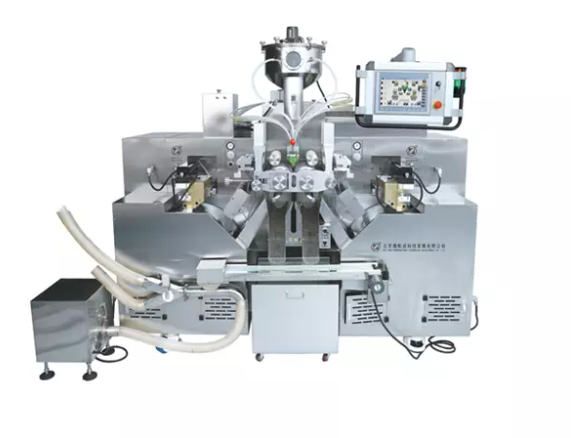

Precision Paintball Making Machine (CE/GMP Certified)

Welcome to Paintball Production Machine Company! It effectively covers operational efficiency, product precision, and long-term cost control to provide reliable support for manufacturing.

Product Center

Products Introduce

Our paintball making machines are automatic, high-performance equipment for industrial-scale production, covering multiple models to meet diverse capacity needs—they feature high automation with PLC touchscreen control and servo motor synchronization (enabling auto mold alignment, filling time adjustment, and real-time gel film thickness correction), production efficiency ranging from 10,800 to 35,000 pcs/hour and filling accuracy within 2% (for 500mg content) with customizable roll molds for different sizes, cost-effectiveness via low oil consumption (<4L/24h) and wear-resistant stainless steel parts, full compliance with CE and GMP standards, and partial configurations including double-layer dehumidification dryers to shorten the drying cycle and boost overall productivity.

Product Advantages

Our industrial-grade paintball making machines stand out with well-designed advantages that directly address key needs in paintball capsule production—effectively covering operational efficiency, product precision, and long-term cost control—to provide reliable support for both small-batch customization and large-scale manufacturing.

High Automation & Intuitive Operation

Equipped with PLC touchscreen control and servo motor synchronization, realizing automatic mold alignment, filling time adjustment, and real-time gel film thickness correction—reducing manual intervention and operational errors. Independent coordinated control of sub-systems makes the interface simple and easy to master, suitable for both new and experienced operators.

Excellent Capacity & Stable Precision

Covers a wide production range from 10,800 to 35,000 pcs/hour, meeting both small-batch and large-scale production needs. Filling accuracy is within 2% (for 500mg content), and roll molds can be customized according to soft capsule size requirements—ensuring consistent product quality.

Cost-Efficiency & Compliance Guarantee

Adopts "quantitative micro-lubrication" design, with oil consumption less than 0.5L/1h; parts in contact with materials are made of corrosion-resistant stainless steel, reducing material waste and equipment maintenance costs. All models comply with CE and GMP standards; some configurations are matched with double-layer dehumidification rotary cage dryers to shorten the drying cycle and improve overall production efficiency.

Application

Application1

Application2

Application3

Service

Pre-Sale Consultation

We conduct in-depth communication to fully understand your specific needs for paintball making machines (such as production scale, product specifications, and compliance requirements). Based on this, we recommend suitable machine models and provide comprehensive solutions, while offering detailed product introductions (including parameters, performance, and operation processes) and professional technical support to help you make informed purchase decisions.

Customized Services

We provide personalized design and production services tailored to your special requirements. Whether it is customizing roll molds for paintball soft capsules of specific sizes, adjusting filling volume ranges, or matching auxiliary equipment (such as dehumidification dryers) according to your production site, we also offer professional technical advice throughout the customization process to ensure the final product meets your unique production needs.

After-Sales Service & Warranty

We offer a 1-year free warranty period starting from the signing of the equipment commissioning acceptance report. During this period, we provide free spare parts for random needs, and are responsible for eliminating all equipment faults as well as replacing and repairing faulty components. When equipment malfunctions occur, we respond within 2 hours upon receiving your call; if the issue cannot be resolved over the phone, our technical team will rush to the site for maintenance within 36 hours. After the warranty period expires, we provide lifelong tracking maintenance services, and only charge the cost price for the spare parts you need.

Technical Support & Training

Our experienced technical personnel (with years of experience in soft capsule equipment assembly and debugging) are responsible for guiding equipment installation and debugging to ensure smooth startup. During the debugging period, we provide free technical training to your technical staff and operators, covering equipment operation, daily maintenance, and fault troubleshooting, until they fully master all necessary skills. We also offer long-term free technical support, and ensure sufficient supply of reliable-quality spare parts to avoid production delays caused by insufficient spare parts.

Company Advantage

Beijing Sinagel Technology Development Co., Ltd., founded in January 1998 and specializing in soft capsule equipment for 20+ years, integrates R&D, production, sales and service into one. Its industry-leading advantages are built around four core dimensions—rooted in the philosophy of "technology as the core and service as the foundation"—covering technological innovation, international compliance, brand reputation, and sustainable safety, which together support its position as a key player in the global soft capsule equipment sector.

Technological R&D & Innovation Advantages

Long-term Focus & Professional Foundation: Founded in January 1998, the company has specialized in soft capsule equipment for 20+ years, integrating R&D, production, sales, and service. It leverages unique aerospace technology advantages to develop high-quality equipment. Industry-leading Innovations: It has created multiple "firsts" in the industry, such as the first full-servo high-speed soft capsule machine, the first PLC-controlled automatic soft capsule machine, the first double-layer rotary cage dryer, and the first fully explosion-proof soft capsule cleaning machine, filling domestic gaps and leading industry development. Intelligent Upgrades: It took the lead in adopting PLC control technology and Siemens WinCC automation software, integrating PLC, motion control, machine vision, and HMI functions on a unified platform to realize intelligent and integrated equipment development.

International Market & Compliance Advantages

Global Market Coverage: Its products have been exported to more than 100 countries and regions, including Europe, America, the United States, Canada, Russia, and Malaysia, gaining recognition as a well-known global provider of soft capsule and drop-pill technology. Strict Compliance Certification: All equipment has passed the EU CE certification, meeting international quality and safety standards, which helps the company smoothly enter and expand in standardized international markets.

Brand Reputation & Service Advantages

Strong Brand Alliances: It has established strategic cooperative relationships with well-known enterprises (e.g., By-Health), reflecting high recognition from industry partners. Award-winning Service Quality: It has won honors such as "After-sales Service Excellence Award" and "Best Partner Award," adhering to the concept of "service as the foundation" and providing full-process support from pre-sales consultation to after-sales maintenance. Customer-Centric Commitment: It takes customer needs as the core, focuses on improving customers’ market competitiveness through high-quality products and services, and has built a good market reputation.

Sustainable Development & Safety Advantages

Green Production Practices: It actively applies environmental protection technologies and materials in production, optimizes processes to improve resource utilization efficiency, reduces waste, and achieves green and sustainable production. Strict Safety & Quality Control: It has established a strict quality management system, covering raw material procurement to product delivery. It also abides by national and international safety regulations and conducts regular employee safety training to ensure safe production and reliable product quality.

Contact Us

As Beijing Sinagel Technology Development Co., Ltd.—an enterprise with 20+ years of experience specializing in soft capsule equipment, integrating R&D, production, sales and service—we always center on your needs. To efficiently respond to your inquiries about equipment, customized service requirements, after-sales support or cooperation intentions, we’ve prepared clear contact channels below; feel free to reach out anytime, and our professional team will provide timely, thoughtful assistance tailored to your needs.

FAQs

Related Blogs

How Does A Softgel Machine Work?

Softgel capsules are popular in the pharmaceutical industry. They offer benefits like precise dosing and bioavailability. But how are these capsules made?In this article, we will explore how a softgel machine works. Learn more about our products at Sinagel.

Read MoreWhat Is The Process of Making Softgels?

Have you ever wondered how softgel capsules are made? These capsules are easy to swallow and offer precise dosing. They are highly valued in pharmaceuticals and nutraceuticals.In this article, we’ll explain the detailed process of making softgels. You’ll learn about each key stage and how modern technology ensures quality.By the end, you’ll understand how machines help produce consistent, high-quality capsules. Learn more about our products at Sinagel

Read MoreWhat Is The Working Principle of Soft Capsule Encpasulator?

How are softgel capsules made? The soft capsule encapsulator creates precise, easy-to-swallow capsules.This article explains how these machines work and the process behind them. You’ll learn about the key components and technology used.By the end, you’ll understand the working principle of soft capsule encapsulators. Learn more about our products at Sinagel.

Read MoreWhat Is Soft Capsule Encapsulation?

Soft capsule encapsulation offers a unique way to deliver active ingredients. It ensures precise dosing and better bioavailability.This article will explain what soft capsule encapsulation is and how it works. You'll learn about the process, equipment, and key benefits.By the end, you’ll understand why softgel capsules are highly effective. Learn more about our products at Sinagel.

Read More

Get Touch With Us

Contact Info

Whether you need to consult about the Paintball Making Machines, confirm customized solution details, or require after-sales support—you can reach us directly via the contact info below. We’ll respond promptly to address your needs in pharmaceuticals, health products, and cosmetics production.

+86-13601283135

English

English