- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-14 Origin: Site

Soft capsule encapsulation offers a unique way to deliver active ingredients. It ensures precise dosing and better bioavailability.

This article will explain what soft capsule encapsulation is and how it works. You'll learn about the process, equipment, and key benefits.

By the end, you’ll understand why softgel capsules are highly effective. Learn more about our products at Sinagel.

Soft capsule encapsulation is the process of creating a soft gelatin shell around a liquid, paste, or semi-solid fill material. The gelatin shell acts as a protective barrier, safeguarding the active ingredients from environmental factors and ensuring precise delivery. This process is highly effective for ingredients that may be unstable or unpleasant in taste, such as oils and certain nutrients.

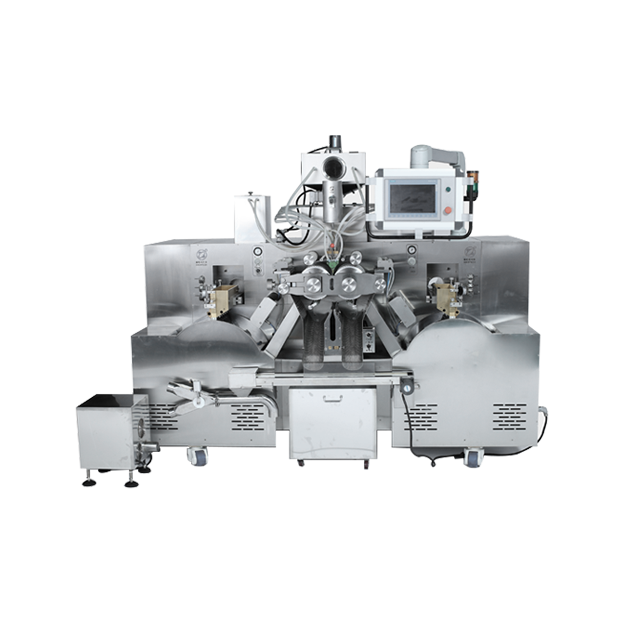

The Soft Capsule Encapsulator is the key equipment used to automate and streamline this process. It helps create consistent, high-quality capsules with the right dosage every time, ensuring that the encapsulation is done efficiently and with minimal waste.

Encapsulation serves several crucial purposes, particularly in the pharmaceutical and nutraceutical industries. Soft capsules protect ingredients, mask unpleasant tastes, and ensure ease of ingestion. They also improve bioavailability, allowing the active ingredient to be absorbed more efficiently in the body. This is especially beneficial for oil-based or hydrophobic substances, which may have poor solubility in water.

With technological advancements, the soft capsule encapsulation process has become increasingly reliable. Machines used for this process are designed to meet various production scales, whether for small experimental runs or large-scale manufacturing.

Compared to traditional tablets and powders, soft capsules offer significant advantages. They are easier to swallow, they mask the taste or odor of unpleasant ingredients, and they provide more accurate and consistent dosing. These capsules also dissolve faster in the body, enhancing the absorption of active ingredients, making them ideal for sensitive compounds.

The ability to tailor the shell and fill material makes soft capsules versatile, allowing them to deliver a variety of active ingredients that might not be suitable for other dosage forms. This flexibility makes soft capsules increasingly popular in the pharmaceutical and nutraceutical industries.

The first step in the soft capsule encapsulation process involves preparing the gelatin shell. Gelatin is combined with water and plasticizers (like glycerin or sorbitol) to form a pliable mixture. This mixture is then heated to ensure the ingredients are well-integrated, forming a flexible, strong outer shell for the softgel capsule.

The use of a Soft Capsule Encapsulator ensures that the gelatin is consistently mixed and melted, providing uniformity in the shell production. This consistency is essential to ensure that the capsules are of uniform size and that they deliver the correct dosage.

The next step is preparing the fill material, which could be a liquid, paste, or suspension. This material must meet specific viscosity and homogeneity requirements to ensure proper encapsulation. Common fill materials include oils, suspensions with active pharmaceutical ingredients (APIs), or hydrophilic and lipophilic bases, depending on the solubility of the API.

Fill materials need to be processed with precision to ensure they are stable and effective within the gelatin shell. The Soft Capsule Encapsulator plays a role in ensuring that the material is evenly distributed and filled into the shell without any air bubbles or inconsistencies.

Fill Material Type | Common Uses |

Oil-based | Fish oil, vitamin E, essential oils |

Hydrophilic | Water-soluble ingredients like vitamins C, B |

Lipophilic | Fat-soluble ingredients like CoQ10, cannabinoids |

Suspensions | Suspensions for poorly soluble ingredients |

The gelatin mixture is then spread into thin ribbons using a Soft Capsule Encapsulator. These ribbons will later be formed into capsules. The equipment ensures uniform thickness and the correct temperature during this phase, ensuring consistency in every capsule formed.

The precision of the encapsulator is vital for achieving the correct dosage and ensuring that the capsules are of high quality.

The next step involves sealing the gelatin ribbons around the fill material to create the soft capsules. The Soft Capsule Encapsulator uses rotary dies to seal and cut the capsules simultaneously. This step ensures uniform size and dosage and ensures the capsules are properly sealed to prevent leakage.

High precision is required during this stage to ensure that each capsule is intact and properly formed. This precision prevents leakage and ensures that each capsule delivers the correct dosage of active ingredients.

Once the capsules are formed, they undergo a drying process to remove excess moisture. This two-stage drying process includes tumble drying, which removes most of the moisture, followed by tray drying, where capsules are stabilized under controlled airflow and humidity conditions.

The drying process is carefully monitored to ensure that the capsules retain their flexibility and integrity, preventing them from becoming too brittle or too soft.

Quality control is a critical step in the soft capsule encapsulation process. Several factors, such as ribbon thickness, fill weight accuracy, and seal integrity, are regularly monitored to ensure consistent quality. Final testing for dissolution, stability, and appearance helps ensure the capsules perform as expected when consumed.

Machines such as the Soft Capsule Encapsulator are equipped with advanced systems that automatically perform quality control checks throughout the encapsulation process. This ensures that each batch of capsules meets the highest standards.

Quality Check | Purpose |

Ribbon Thickness | Ensures uniform shell thickness and consistency |

Fill Weight Accuracy | Verifies that each capsule contains the correct amount of fill material |

Seal Integrity | Checks that the seals are strong and leak-proof |

Dissolution Rate | Confirms that capsules dissolve at the correct rate |

The Soft Capsule Encapsulator is a specialized piece of equipment designed to automate the encapsulation process. Key components include:

● Gelatin Tank: Holds the liquid gelatin mixture.

● Ribbon Former: Creates thin, uniform gelatin ribbons.

● Filling Unit: Injects the fill material into the gelatin ribbons.

● Rotary Dies: Seal and cut the capsules into the desired shape.

● Drying System: Ensures proper moisture removal from the capsules.

Precision is crucial to ensure the integrity and consistency of each capsule. The equipment used in the soft capsule encapsulation process must maintain tight control over temperature, speed, and pressure to ensure uniformity in capsule size, shape, and dosage.

With advanced technology, Soft Capsule Encapsulators now offer greater flexibility and higher automation levels, making it easier for manufacturers to meet both small and large production demands.

Recent advancements in encapsulation technology have improved efficiency and reduced production costs. Automation has also made the process more streamlined, allowing for faster production times and higher output. Furthermore, innovations in plant-based gelatin alternatives are catering to growing demand for vegan and halal products, expanding the possibilities for softgel capsules.

Component | Function |

Gelatin Tank | Holds and heats the gelatin mixture |

Ribbon Former | Forms thin, uniform gelatin ribbons |

Filling Unit | Injects the fill material into the ribbons |

Rotary Dies | Seals and cuts the capsules into shape |

Drying System | Removes excess moisture from the softgel capsules |

One of the main quality control measures in the soft capsule encapsulation process is ensuring consistent gelatin thickness and fill weight. Regular inspections are conducted to ensure the gelatin ribbons are uniform and that each capsule contains the correct amount of active ingredient.

The capsule seals must be strong enough to prevent leaks or damage. Quality control checks ensure that the capsules are sealed properly and meet all safety standards. Burst tests and visual inspections help confirm the strength of the seals.

Before packaging, softgel capsules undergo final testing to ensure they meet required stability and dissolution standards. These tests ensure that the capsules will perform as expected once ingested, providing the intended benefits.

As consumer demand for vegan and halal products grows, plant-based gelatin alternatives are becoming more popular in softgel production. These alternatives, such as Hydroxypropyl Methylcellulose (HPMC), offer similar properties to traditional gelatin but cater to a broader audience.

New coating technologies, including enteric and delayed-release coatings, are enhancing the bioavailability of active ingredients. These coatings allow the capsules to dissolve at the right location in the digestive tract, ensuring optimal absorption.

Automation continues to improve the efficiency of softgel production. With fewer manual interventions, these innovations have reduced labor costs and increased the speed of production, allowing manufacturers to meet growing demand more effectively.

Soft capsule encapsulation is a precise process, ensuring consistency and quality at every stage. From forming the gelatin shell to final testing, the process is optimized for effectiveness. With advancements in technology, the future of encapsulation is bright. At Sinagel, our products deliver exceptional value by meeting the increasing demands of the pharmaceutical and nutraceutical industries, ensuring high-quality, reliable results.

A: Soft capsule encapsulation is the process of filling gelatin shells with liquids or semi-solids to create softgel capsules. It ensures precise dosing and improves bioavailability.

A: Encapsulation helps protect sensitive ingredients from degradation and ensures more effective absorption. It provides a convenient and accurate way to deliver active ingredients.

A: A soft capsule encapsulator forms gelatin ribbons, injects fill material, and seals the capsules into uniform shapes. It automates the process, ensuring consistency and quality.

A: Soft capsule encapsulation offers precise dosing, better bioavailability, and protection for sensitive ingredients, making it ideal for supplements and pharmaceutical products.