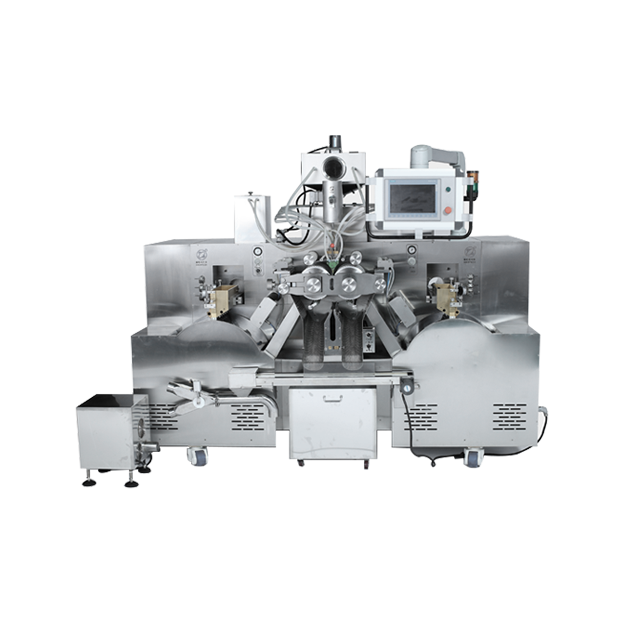

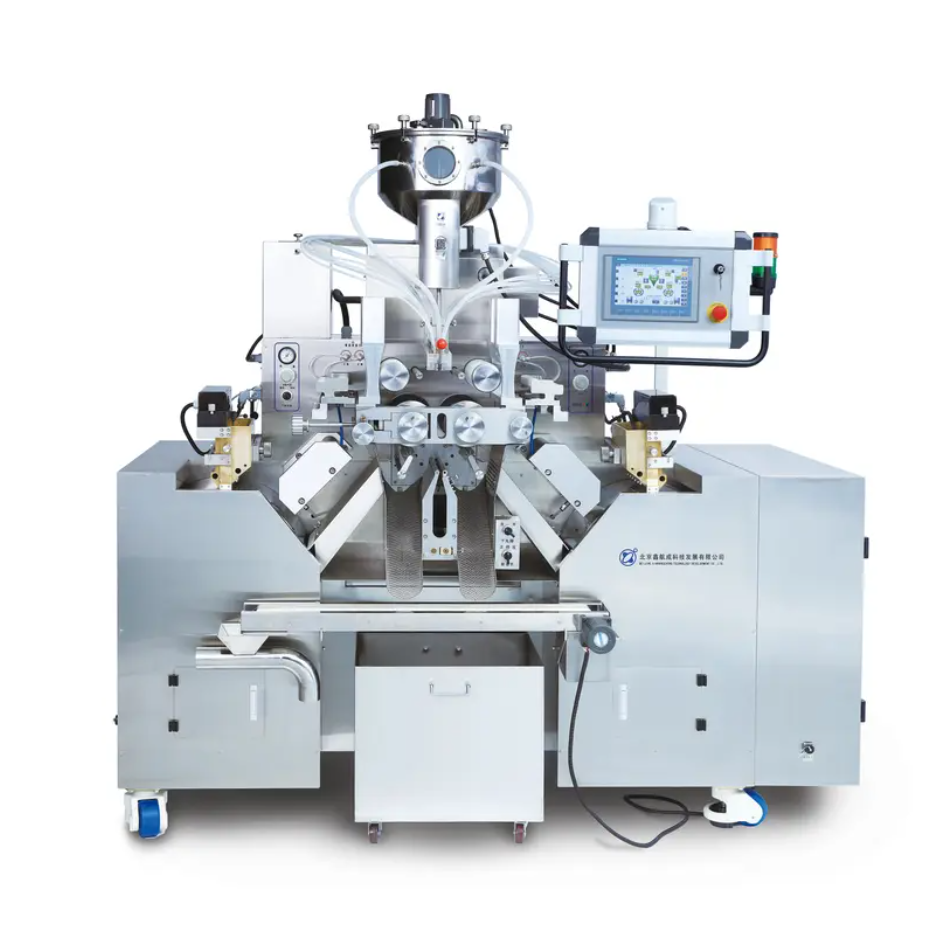

Custom Softgel Encapsulation Machine – Stable Performance & Versatile Use

Welcome to explore our Softgel Encapsulation Machine (YWJ Series)! It covers small-scale R&D, medium and large-scale production, fitting pharma, health, and cosmetics industries. We offer custom designs and stable performance to meet your unique needs—feel free to reach out for details!

Product Center

Products Introduce

Our Softgel Encapsulation Machine (YWJ Series) is specialized equipment for softgel production, widely applied in the pharmaceutical, health product, and cosmetics industries. It covers three models to fit diverse production needs: YWJ100 for small-scale R&D or experimental use, YWJ120 (equipped with servo motor and PLC system) for medium-sized operations, and YWJ250 for high-automation mass production. We provide custom design and manufacturing services (suitable for labs to large enterprises) and tailor-made die rollers—since the shape and size of softgels depend on the die rollers. All machines boast advanced technology, sleek appearance, and stable performance to meet your specific production requirements.

Product Advantages

Our YWJ Series Softgel Encapsulation Machine is designed to address diverse production pain points, with core advantages that span scenario adaptability, operational stability, and customization—all tailored to fit your needs in pharmaceuticals, health products, and cosmetics.

Full-Scenario Adaptability

Our YWJ Series covers small-scale R&D (YWJ100), medium production (YWJ120), and mass manufacturing (YWJ250), meeting needs from labs to large enterprises.

Stable & Advanced Performance

With years of R&D upgrades, all machines feature advanced tech (e.g., servo motor, PLC for YWJ120), sleek design, and reliable operation to reduce defect rates.

High Customization

We offer tailor-made machines (based on budget/needs) and custom die rollers—key for defining softgel shape/size—to solve unique production demands.

Application

Application1

Application2

Application3

Service

Pre-Sale Consultation

We conduct in-depth communication to understand your specific needs, then recommend suitable Softgel Encapsulation Machine models and solutions. We also provide detailed product introductions and professional technical support to help you make informed purchasing decisions.

After-Sales Service

We offer comprehensive after-sales support, including product warranty, repair, and replacement. For equipment failures, we respond within 2 hours of receiving your notice; if phone troubleshooting fails, we arrive on-site for maintenance within 36 hours. You enjoy 1 year of free technical support and spare parts (for random needs) after equipment acceptance. Post-warranty, we provide lifelong maintenance tracking, with spare parts charged only at cost.

Customized Services

Based on your production scale, budget, and special requirements, we offer personalized design and manufacturing of Softgel Encapsulation Machines. We also provide tailored die rollers (key for softgel shape/size) and professional technical advice to meet your unique production demands.

Technical Support

Our experienced technicians guide equipment installation and debugging. During debugging, we offer free technical training to your staff—covering operation, maintenance, and troubleshooting—until they fully master the skills. We also provide long-term free technical support and ensure sufficient, reliable, and timely supply of spare parts.

Company Advantage

As a professional provider of softgel encapsulation equipment, we distinguish ourselves in the industry through four core competitive edges—strong R&D capabilities, tailored solution expertise, comprehensive lifecycle services, and deep industry application experience—all designed to support your production needs across pharmaceuticals, health products, and cosmetics.

Strong R&D & Technical Strength

We have a professional R&D team with years of experience in softgel equipment development. Our core product, the YWJ Series Softgel Encapsulation Machine, has undergone multiple rounds of technical iterations—from optimizing servo motor control to enhancing PLC system stability—to ensure advanced performance and meet evolving industry production demands. We also maintain in-house expertise in key components like custom die rollers, ensuring technical coherence across the entire production line.

Tailored Solution Capabilities

Unlike one-size-fits-all equipment providers, we focus on delivering customized solutions based on client needs. Whether you are a lab requiring small-batch R&D equipment (YWJ100), a medium enterprise needing stable production lines (YWJ120), or a large manufacturer pursuing mass production (YWJ250), we adjust machine configurations, die roller specs, and even production process designs to align with your budget, product types, and scale. This flexibility helps solve unique pain points that standard equipment cannot address.

Comprehensive Full-Lifecycle Service

We have built a seamless service system covering the entire equipment lifecycle. Pre-sales, we provide in-depth demand analysis and model recommendations; during implementation, our technicians offer on-site installation, debugging, and staff training. Post-sales, we guarantee 2-hour response to maintenance requests, 36-hour on-site support (if needed), 1 year of free spare parts, and lifelong maintenance tracking. This end-to-end support minimizes downtime and ensures long-term stable operation of your equipment.

Deep Industry Application Experience

We have accumulated rich experience across the pharmaceutical, health product, and cosmetics sectors—three core fields for softgel production. We understand the strict quality standards of the pharmaceutical industry (e.g., compliance with production regulations), the diverse formula needs of health products (e.g., fish oil, collagen), and the freshness/portability requirements of cosmetics (e.g., essence capsules). This industry insight allows us to better match equipment functions to your specific application scenarios, reducing trial-and-error costs for your production.

Contact Us

Whether you have questions about our YWJ Series Softgel Encapsulation Machine, need details on customized solutions, or require support for pre-sales consultation or after-sales service—we’re here to assist you. Reach out through the following channels, and our team will respond promptly to address your production and equipment needs across pharmaceuticals, health products, and cosmetics.

FAQs

Resource

Brochure

Video

Related Blogs

How Does A Softgel Machine Work?

Softgel capsules are popular in the pharmaceutical industry. They offer benefits like precise dosing and bioavailability. But how are these capsules made?In this article, we will explore how a softgel machine works. Learn more about our products at Sinagel.

Read MoreWhat Is The Process of Making Softgels?

Have you ever wondered how softgel capsules are made? These capsules are easy to swallow and offer precise dosing. They are highly valued in pharmaceuticals and nutraceuticals.In this article, we’ll explain the detailed process of making softgels. You’ll learn about each key stage and how modern technology ensures quality.By the end, you’ll understand how machines help produce consistent, high-quality capsules. Learn more about our products at Sinagel

Read MoreWhat Is The Working Principle of Soft Capsule Encpasulator?

How are softgel capsules made? The soft capsule encapsulator creates precise, easy-to-swallow capsules.This article explains how these machines work and the process behind them. You’ll learn about the key components and technology used.By the end, you’ll understand the working principle of soft capsule encapsulators. Learn more about our products at Sinagel.

Read MoreWhat Is Soft Capsule Encapsulation?

Soft capsule encapsulation offers a unique way to deliver active ingredients. It ensures precise dosing and better bioavailability.This article will explain what soft capsule encapsulation is and how it works. You'll learn about the process, equipment, and key benefits.By the end, you’ll understand why softgel capsules are highly effective. Learn more about our products at Sinagel.

Read More

Get Touch With Us

Contact Info

Whether you need to consult about the YWJ Series Softgel Encapsulation Machine, confirm customized solution details, or require after-sales support—you can reach us directly via the contact info below. We’ll respond promptly to address your needs in pharmaceuticals, health products, and cosmetics production.

+86-13601283135

English

English