Product Category

Sinagel offers a comprehensive range of high-quality softgel manufacturing equipment, designed to meet the diverse needs of the pharmaceutical, nutraceutical, and cosmetic industries.

Our product categories include:

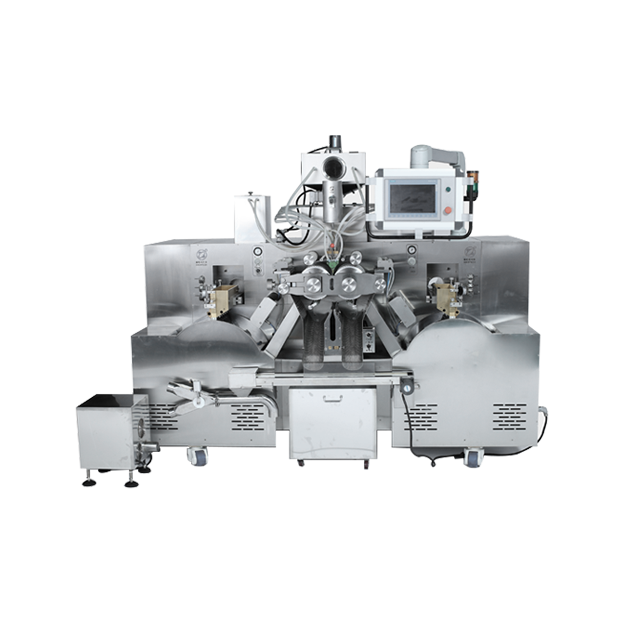

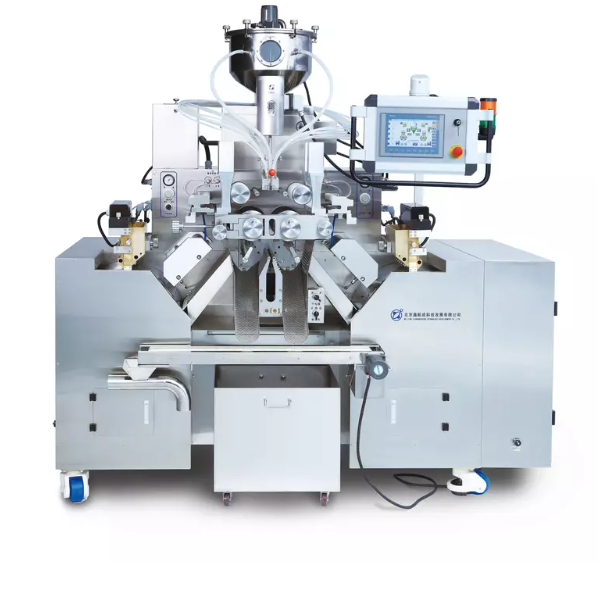

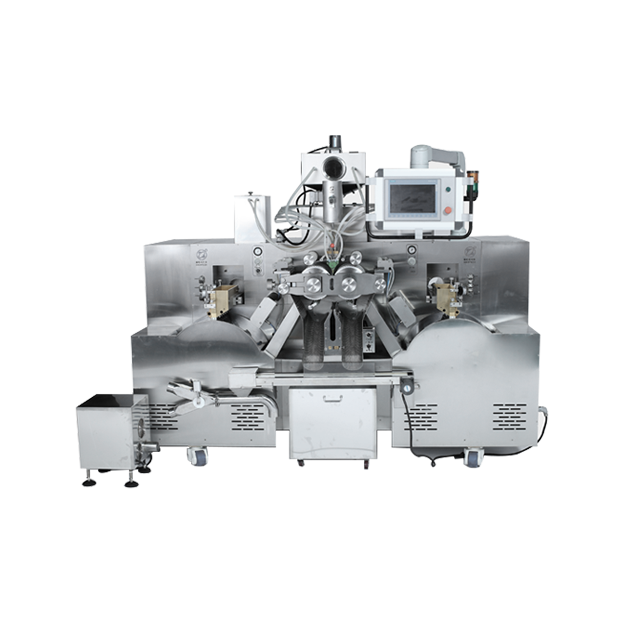

1. Softgel Encapsulators: Our encapsulation machines are engineered for precision and efficiency, ensuring consistent quality in softgel production.

Key models include:

Paintball Production Machine: Specialized equipment for producing gelatin capsules filled with paintballs, catering to specific industrial applications.

Cosmetic Capsule Production Machine: Designed for the encapsulation of cosmetic ingredients, offering gentle processing to maintain ingredient integrity.

Vege Capsule Production Machine: Tailored for producing plant-based softgel capsules, meeting the growing demand for vegetarian and vegan products.

Fish Oil Filling Machine: Optimized for the precise filling of fish oil into softgel capsules, ensuring accurate dosage and product stability.

2. Softgel Drying Systems: Our drying systems are essential for the post-encapsulation process, ensuring optimal moisture content and enhancing capsule quality.

3. Gelatin Melting Systems: These systems provide controlled heating and melting of gelatin, ensuring a consistent and high-quality film for capsule formation.

4. Medicine Preparation Systems: Designed to prepare and mix active pharmaceutical ingredients with excipients, ensuring uniformity and quality in the encapsulation process.

5. Sorting Machines

Product Feature

High Efficiency Production

Our softgel machines are designed for maximum output with minimal downtime, ensuring smooth and continuous production. Perfect for both small-scale and large-scale operations.

Precision and Consistency

Advanced encapsulation technology guarantees uniform capsule size and weight, reducing material waste and improving product quality.

User-Friendly Operation

Intuitive control panels and automated systems make operation simple and reduce the need for extensive training.

Energy-Saving & Environmentally Friendly

Optimized motor systems and efficient heating solutions lower energy consumption while maintaining high performance.

Application

Softgel machines are widely applied across multiple industries, providing precise, efficient, and reliable encapsulation solutions. In the pharmaceutical industry, they ensure accurate dosage and consistent quality for medicinal capsules, vitamins, and other pharmaceutical products. In the nutraceutical and dietary supplement sector, they are ideal for producing fish oil, herbal extracts, and vitamins, delivering smooth, uniform, and visually appealing softgel capsules. Additionally, these machines are used in the cosmetic and personal care market for encapsulating ingredients such as collagen and essential oils, as well as in the food industry for creating edible oils, flavor oils, and functional food capsules. Softgel machines also support research and pilot production, allowing manufacturers to test new formulations and optimize production processes before scaling up, making them versatile tools for both commercial and experimental applications.

Manufacturing Capabilities

Our company boasts state-of-the-art manufacturing facilities dedicated to the production of high-quality softgel machines. Equipped with advanced CNC machinery, precision assembly lines, and automated testing systems, we ensure every machine meets strict industry standards. Our experienced engineering team oversees every stage of production, from component fabrication to final assembly, guaranteeing reliability, efficiency, and longevity of each machine. With a focus on innovation and continuous improvement, we are capable of producing a wide range of softgel machines, from pilot-scale units to fully automated commercial production lines, tailored to meet diverse client requirements. Quality control is integrated throughout the manufacturing process, ensuring that every machine delivers consistent performance, minimal downtime, and compliance with international standards.

Quality Assurance & Compliance

Every softgel machine we manufacture undergoes strict quality inspection and performance testing to ensure stable operation and long service life. Our production process fully complies with international manufacturing standards, including GMP and CE certification. From raw material selection to final assembly, every detail is carefully monitored by our quality control team. This commitment to quality allows us to deliver reliable, high-performance softgel machines that meet the demanding requirements of the pharmaceutical and nutraceutical industries.

Technical Support & Service

We provide comprehensive technical support and service to ensure our clients achieve optimal performance from every softgel machine. Our professional engineering team offers full installation guidance, operation training, and process optimization tailored to customer needs. In addition to on-site service, we provide remote technical assistance and real-time troubleshooting to minimize downtime and maintain production efficiency. Regular maintenance programs and spare parts supply are also available to guarantee long-term reliability and consistent machine operation. With a strong global service network, we are committed to delivering prompt, efficient, and professional support for every customer, wherever they are.

Customer Success & Global Presence

Trusted by Global Partners

Our softgel machines are trusted by pharmaceutical, nutraceutical, and cosmetic manufacturers around the world. With years of industry experience and consistent quality, we have built long-standing relationships with clients across more than 60 countries.

Proven Results Across Industries

From Asia and Europe to North and South America, our equipment operates in diverse production environments, delivering high output, reliability, and compliance with international standards.

Strong Global Distribution Network

We take pride in supporting our partners’ success through continuous innovation and dedicated after-sales service. Our global technical team provides prompt assistance to ensure uninterrupted production and stable machine performance.

Commitment to Long-Term Partnerships

By combining advanced manufacturing capabilities with worldwide service coverage, we aim to create sustainable, long-term partnerships that drive growth and success for our customers across the globe.

- Name

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- 2024 Sinagel Eighth Edition Product Brochure.pdf

- 2025-12-05

- 41.48MB

- 434

-

- Download

- Copy Link

Why Choose Us

With decades of expertise in softgel encapsulation technology, we have developed a deep understanding of customer needs and industry standards, allowing us to deliver highly reliable and efficient machines for global clients.

Over 20 Years of Manufacturing Experience

Our factory is equipped with precision CNC machines, automated assembly lines, and rigorous quality testing systems to ensure consistent performance and long-term durability in every softgel machine we produce.

Advanced Production Facilities

A dedicated engineering and research team continuously improves machine design, enhances automation, and integrates the latest technologies to support pharmaceutical and nutraceutical production trends.

Strong R&D and Innovation Capability

Related Product

FAQs

Contact Us

Looking for the right Softgel Machine solution for your production needs? Our team of experts is ready to help you choose the most suitable model and provide personalized technical guidance. Whether you’re starting a new project or expanding an existing production line, we offer tailored solutions to ensure efficiency, quality, and reliability.

Related Blogs

-

Have you ever wondered how softgel capsules are made? These capsules are easy to swallow and offer precise dosing. They are highly valued in pharmaceuticals and nutraceuticals.In this article, we’ll explain the detailed process of making softgels. You’ll learn about each key stage and how modern technology ensures quality.By the end, you’ll understand how machines help produce consistent, high-quality capsules. Learn more about our products at SinagelIndustry Knowledge

Have you ever wondered how softgel capsules are made? These capsules are easy to swallow and offer precise dosing. They are highly valued in pharmaceuticals and nutraceuticals.In this article, we’ll explain the detailed process of making softgels. You’ll learn about each key stage and how modern technology ensures quality.By the end, you’ll understand how machines help produce consistent, high-quality capsules. Learn more about our products at SinagelIndustry Knowledge -

How are softgel capsules made? The soft capsule encapsulator creates precise, easy-to-swallow capsules.This article explains how these machines work and the process behind them. You’ll learn about the key components and technology used.By the end, you’ll understand the working principle of soft capsule encapsulators. Learn more about our products at Sinagel.Industry Knowledge

How are softgel capsules made? The soft capsule encapsulator creates precise, easy-to-swallow capsules.This article explains how these machines work and the process behind them. You’ll learn about the key components and technology used.By the end, you’ll understand the working principle of soft capsule encapsulators. Learn more about our products at Sinagel.Industry Knowledge

Keep in Touch With Us

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Tel: +86-13601283135

E-mail:chinasoftgel@outlook.com

English

English