- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

Automatic capsule filling machines have transformed pharmaceutical manufacturing by enhancing efficiency and streamlining processes. These machines are essential for handling a wide range of formulations, including liquid-filled capsules, fish oil, and softgel encapsulation. In this article, we’ll explore the key benefits, functionality, and significance of these machines in modern capsule production.

Automatic capsule filling machines offer numerous advantages that transform capsule production processes. These machines bring enhanced production speed and efficiency, ensuring manufacturers can meet growing demand without compromising quality.

One of the most notable benefits is faster cycle times for capsule machines. Automatic systems fill thousands of capsules per hour, significantly outpacing manual or semi-automatic methods. This speed boost results in enhanced productivity with less downtime. Reduced setup time capsule filling also contributes to quicker transitions between batches, enabling manufacturers to respond swiftly to market needs.

Precision capsule filling technology embedded in these machines guarantees improved precision in capsule filling. This consistency ensures every capsule contains the exact dosage, which is critical for pharmaceuticals and nutraceuticals. The performance benefits of automatic capsule fillers minimize product variability, leading to higher quality and customer trust.

Automating the capsule filling process reduces the need for extensive manual labor. This reduction in labor costs allows staff to focus on other value-added tasks. Additionally, fewer human interventions decrease the risk of errors and contamination, contributing to overall operational efficiency.

Automatic capsule filling machines are designed with hygiene in mind. Their closed systems limit exposure to contaminants, supporting compliance with strict pharmaceutical safety standards. Enhanced productivity with capsule filling automation also means fewer touchpoints, reducing contamination risks and promoting safer working environments.

Modern machines can handle a wide variety of capsule types, including hard gelatin, HPMC, and liquid-filled capsules, such as those processed by liquid capsule filling machines or softgel encapsulators. This versatility allows manufacturers to diversify their product lines without needing separate equipment for each capsule type, increasing operational flexibility.

Automatic capsule filling machines significantly enhance operational efficiency, transforming the production workflow into a streamlined, high-performance process. These machines integrate advanced technologies that reduce manual interventions, optimize throughput, and ensure consistent product quality.

By automating the entire capsule filling sequence—from capsule feeding and separation to filling and locking—these machines eliminate bottlenecks common in manual or semi-automatic processes. The faster cycle times for capsule machines allow manufacturers to produce thousands of capsules per hour, boosting overall throughput. Reduced setup time capsule filling also plays a crucial role; quick changeover between batches minimizes downtime, enabling manufacturers to respond promptly to varying production demands. This seamless workflow integration increases efficiency in capsule filling processes, making production more agile and scalable.

Modern automatic capsule filling machines come equipped with real-time monitoring systems that track critical parameters such as fill weight, capsule integrity, and machine performance. This precision capsule filling technology ensures improved precision in capsule filling and immediate detection of any deviations. Data logging capabilities provide comprehensive documentation for quality control and regulatory compliance, enabling manufacturers to maintain traceability and quickly address potential issues. These technical improvements in capsule filling machines contribute to reduced waste and consistent product quality, reinforcing the performance benefits of automatic capsule fillers.

Automatic capsule filling machines are designed for easy integration with upstream and downstream equipment, such as capsule polishing machines, liquid capsule filling machines, and packaging lines. This connectivity creates a continuous production environment that minimizes manual handling and accelerates the entire manufacturing cycle. For example, linking a softgel encapsulator or a fish oil filling machine with the capsule filler ensures synchronized operation, reducing idle times and enhancing overall equipment effectiveness (OEE). Such integration supports enhanced productivity with capsule filling automation and maximizes return on investment (ROI) by leveraging the full potential of the production line.

Tip: To maximize operational efficiency, choose automatic capsule filling machines with built-in real-time monitoring and easy integration capabilities, ensuring a smooth, data-driven production workflow that minimizes downtime and boosts output.

Automatic capsule filling machines represent a smart investment for pharmaceutical and nutraceutical manufacturers aiming to boost efficiency while controlling costs. While the initial purchase price may be higher than manual or semi-automatic options, the long-term financial benefits far outweigh upfront expenses.

One of the most significant cost advantages of automatic capsule filling machines is the reduction in labor costs. By automating capsule feeding, filling, and sealing, these machines require fewer operators, freeing staff to focus on other critical tasks. This labor reduction translates into substantial savings over time, especially in high-volume production environments.

Moreover, precision capsule filling technology minimizes material waste. Accurate dosing ensures each capsule contains the exact amount of formulation, reducing costly overfills or rejects. This improved precision in capsule filling directly contributes to lower raw material consumption and less product wastage, enhancing overall cost-effectiveness.

Automatic capsule fillers incorporate advanced tamping and dosing systems that ensure consistent fill weights and uniform capsule sealing. This consistency reduces the frequency of defective capsules, which otherwise lead to rework or disposal costs. Additionally, real-time monitoring and quality control features help identify and correct errors promptly, preventing large batches of compromised product.

For liquid capsule filling machines and softgel encapsulators, precise control over liquid volume and encapsulation conditions further reduces spillage and formulation loss. These technical improvements in capsule filling machines help manufacturers optimize yield and maximize ROI.

When evaluating the return on investment (ROI) for automatic capsule filling machines, it’s essential to consider factors beyond purchase price. Faster cycle times for capsule machines mean more capsules produced per hour, increasing throughput and revenue potential. Reduced setup time capsule filling also lowers downtime between batches, improving operational efficiency.

Integration capabilities with other production equipment, such as fish oil filling machines or softgel manufacturing equipment, can streamline workflows and amplify productivity gains. These performance benefits of automatic capsule fillers translate into quicker payback periods and stronger financial returns.

Additionally, investing in machines with modular designs and easy maintenance features can reduce long-term service costs and extend equipment lifespan. Choosing equipment from reputable manufacturers with solid after-sales support ensures sustained performance and minimizes unexpected expenses.

Tip: To maximize your capsule filling machine ROI, prioritize models offering quick changeover, real-time monitoring, and precise dosing technology—these features reduce waste, labor costs, and downtime, accelerating your investment payback.

In the pharmaceutical and nutraceutical industries, ensuring compliance and quality assurance is non-negotiable. Automatic capsule filling machines play a crucial role in meeting these high standards, thanks to their advanced design and technology.

Automatic capsule filling machines are engineered to comply with stringent industry regulations such as Good Manufacturing Practices (GMP) and ISO standards. These machines feature hygienic designs with smooth, easy-to-clean surfaces that prevent contamination. By automating the filling process, they reduce human contact, which minimizes the risk of product contamination and helps manufacturers maintain consistent quality. This adherence to regulatory requirements is vital for gaining approvals and maintaining consumer trust.

Modern capsule filling machines incorporate real-time monitoring systems that track key parameters like fill weight, capsule integrity, and machine performance. This precision capsule filling technology ensures improved precision in capsule filling, reducing variability and defects. Automated sensors detect anomalies instantly, allowing operators to address issues before they affect large batches. Data logging and analytics further support quality control by providing detailed insights into production trends and potential problem areas. These technical improvements in capsule filling machines enhance product quality and reduce waste.

Traceability is essential for regulatory compliance and product safety. Automatic capsule filling machines generate comprehensive batch records, including fill weights, machine settings, and production timestamps. This documentation simplifies audits and regulatory inspections by providing transparent, reliable data. It also enables quick identification and recall of any defective batches, protecting both consumers and the manufacturer’s reputation. Integration with enterprise resource planning (ERP) systems further streamlines documentation and ensures all quality assurance processes are well documented.

Automatic capsule filling machines excel in adapting to diverse production needs, making them indispensable in today's fast-evolving pharmaceutical and nutraceutical markets. Their flexibility allows manufacturers to meet changing demands efficiently without compromising quality or speed.

Markets vary widely in capsule types, formulations, and batch sizes. Modern automatic capsule filling machines are designed with adaptability in mind, enabling quick transitions between product lines. For example, a manufacturer can switch from producing standard hard gelatin capsules to liquid-filled softgels using a liquid capsule filling machine or softgel encapsulator. This adaptability supports product diversification and rapid response to consumer trends, enhancing competitiveness.

Whether filling powders, pellets, granules, or liquids, these machines accommodate a broad range of formulations. Softgel manufacturing equipment, for instance, handles viscous oils like fish oil with precision, ensuring uniform fill volume and capsule integrity. The versatility to process various materials reduces the need for multiple specialized machines, saving space and investment costs.

Capsule sizes can range from tiny to large, depending on the application. Automatic capsule filling machines feature adjustable settings and interchangeable tooling to handle different capsule sizes seamlessly. This precision capsule filling technology ensures that each capsule, regardless of size, is filled accurately and consistently. Quick changeover capabilities further reduce setup time, allowing manufacturers to switch sizes with minimal downtime.

Tip: When selecting automatic capsule filling machines, prioritize models with modular designs and user-friendly interfaces that support fast adjustments and handle multiple capsule types and sizes efficiently.

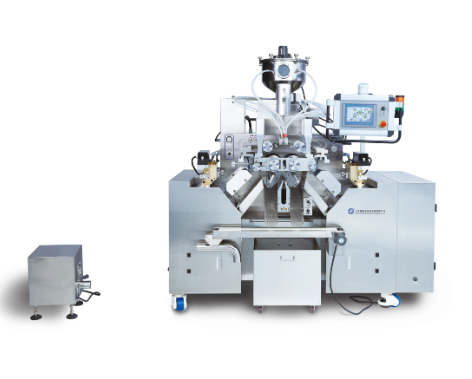

Emerging trends in automatic capsule filling machines emphasize speed, precision, and efficiency. These innovations promise long-term benefits for the pharmaceutical and nutraceutical industries, enhancing productivity and quality. Investing in automatic capsule fillers offers significant advantages, such as reduced labor costs and improved product consistency. Companies like Beijing Sinagel Technology Development Co., Ltd. provide advanced solutions, ensuring manufacturers stay competitive and meet market demands effectively. The unique features of their products deliver substantial value, making them a wise investment for future growth.

A: Liquid Capsule Filling Machines offer improved precision in capsule filling by accurately dosing liquid formulations, such as fish oil, into capsules. This ensures consistent product quality and minimizes wastage, enhancing efficiency in capsule filling processes.

A: A Softgel Encapsulator enhances productivity by automating the encapsulation process, reducing manual labor, and improving hygiene standards. Its technical advancements ensure faster cycle times for capsule machines and consistent fill weights, contributing to overall operational efficiency.

A: Capsule filling automation provides advantages such as reduced setup time capsule filling, improved precision in capsule filling, and lower labor costs. These benefits lead to enhanced productivity and a stronger return on investment (ROI).

A: Automatic capsule filling machines use precision capsule filling technology to maintain consistent dosing and quality control measures. Real-time monitoring systems detect anomalies, ensuring compliance with industry standards and reducing product variability.

A: Yes, automatic capsule filling machines are versatile and can process various capsule types, including hard gelatin, HPMC, and liquid-filled capsules. This flexibility allows manufacturers to diversify product lines without needing separate equipment for each type.