- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

Soft capsule encapsulation ensures precise doses and enhanced bioavailability. But how are these capsules made?

In this article, we will explore the methods used for soft capsule encapsulation. You'll learn about the different techniques and their benefits.

By the end, you'll understand how these methods improve capsule quality. Learn more about our products at Sinagel.

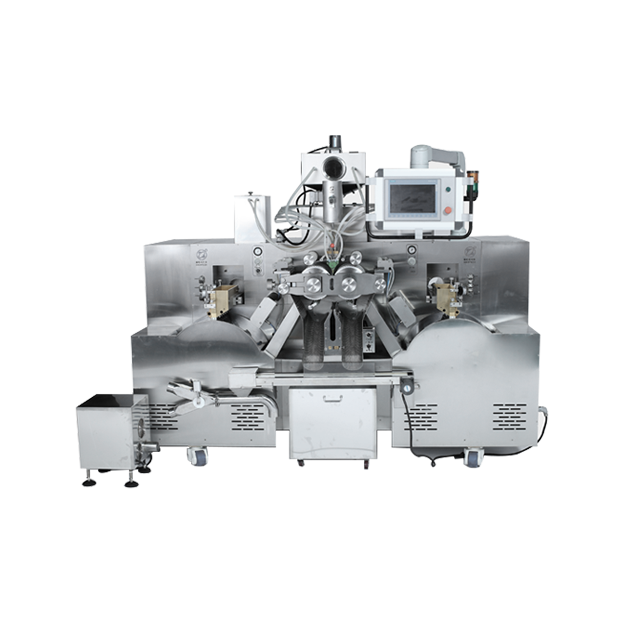

Soft capsules are made by encapsulating liquid, semi-liquid, or gel-like substances inside a gelatin shell. This process ensures the safe delivery of active ingredients, which can be sensitive to environmental conditions such as light, air, or moisture. The soft capsule encapsulator plays a key role in efficiently producing these capsules with uniformity and precision.

Choosing the right encapsulation method is critical for ensuring that the soft capsules meet specific quality standards, such as consistent dosage, stability, and effectiveness. The encapsulation method used also impacts bioavailability, which refers to how effectively the body absorbs the active ingredients.

The rotary die method is one of the most widely used techniques for soft capsule production. In this method, two gelatin ribbons are fed between rotating dies that press and seal the ribbons to form capsules. The process is fast, precise, and capable of producing large volumes of softgel capsules.

This method is ideal for producing both liquid-filled and gel-filled soft capsules, with a high level of accuracy in ensuring consistent size and dosage. By using a soft capsule encapsulator, manufacturers can automate the encapsulation process, improving both efficiency and quality.

This method provides several key benefits:

● High-speed production suitable for large-scale operations.

● Consistency in capsule size and fill weight.

● Precision in the formation of capsules.

With the ability to handle high-volume production, rotary die encapsulation is ideal for manufacturers aiming to meet growing market demands.

Benefit | Description |

High-speed production | Ideal for large-scale operations, ensuring quick production of soft capsules. |

Consistency in capsule size | Ensures that every capsule is uniform in size and weight, maintaining quality across batches. |

Precision in capsule formation | Accurate capsule formation ensures the active ingredient is evenly distributed. |

The rotary die method is particularly suitable for mass production of soft capsules, especially in industries where consistent quality is essential, such as pharmaceuticals, nutraceuticals, and health supplements.

The two-phase method involves two distinct phases during the encapsulation process. First, the gelatin forms the outer shell, then the fill material is injected into the capsule, and the process continues with sealing and additional filling. This method offers greater flexibility and is often used for products requiring multiple active ingredients or a controlled-release formulation.

The two-phase method allows for complex capsule formulations, such as dual or multi-phase release, which makes it ideal for capsules with specialized release profiles.

This method is particularly useful when encapsulating products that require different release timings, such as time-release medications or supplements with multi-functional active ingredients.

While gelatin is commonly used for soft capsule production, alternatives such as HPMC (Hydroxypropyl Methylcellulose) are gaining popularity due to growing consumer demand for vegan and halal products. These alternatives serve the same function as gelatin but are made from plant-based materials.

Gelatin-free encapsulation provides a suitable option for consumers with dietary restrictions. However, these alternatives require precise temperature control and may involve adjustments to the soft capsule encapsulator for optimal performance.

Advantage/Challenge | Description |

Advantage | Provides an option for consumers with dietary restrictions, such as vegan or halal requirements. |

Challenge | Requires precise temperature control and adjustments to the encapsulation machine for optimal performance. |

Temperature plays a crucial role in the soft capsule encapsulation process. The viscosity and consistency of gelatin, which forms the capsule shell, are highly sensitive to temperature changes. A slight variation in temperature can significantly impact the quality of the final product, affecting capsule formation, sealing, and texture. Maintaining the right temperature ensures that the gelatin behaves as required, allowing for smooth and uniform encapsulation.

To maintain the ideal temperature, modern soft capsule encapsulators are equipped with specialized systems that regulate the temperature of both the gelatin and the fill material. These systems monitor and adjust the temperature in real-time to ensure consistency across the entire batch. The equipment used is designed to control the gelatin's temperature within a narrow range, preventing any fluctuation that could lead to defects in the capsules. This precision in temperature regulation is key to producing soft capsules of the highest quality.

Temperature control ensures that the gelatin maintains its intended form, preventing irregularities in the capsule's shape or texture. If the temperature is too high, the gelatin may become too thin or sticky, causing inconsistent capsule formation. If the temperature is too low, the gelatin could become too thick, leading to difficulty in forming capsules. Temperature precision is especially important when producing capsules with multiple layers or those designed for controlled-release formulations. By keeping the temperature within the ideal range, manufacturers can guarantee high-quality soft capsules with uniformity and proper functionality.

Modern soft capsule encapsulators are increasingly utilizing automation and artificial intelligence (AI) to improve production efficiency and reduce the potential for human error. These advanced systems enable real-time adjustments to production parameters such as speed, temperature, and the flow of fill material. By constantly monitoring these variables, the systems can optimize the encapsulation process, leading to more consistent and high-quality products.

Advancements in automation and AI have revolutionized soft capsule production. The integration of these technologies has significantly increased production speed while ensuring high consistency. Automated systems minimize downtime, enabling manufacturers to produce larger quantities of capsules more efficiently. Additionally, the precision provided by these systems results in improved product quality, ensuring that each capsule meets strict standards for dosage and size.

The rise of AI and automation has also led to significant innovations in capsule design. Manufacturers can now easily customize the shape, size, and coating of soft capsules, offering greater flexibility to cater to specific consumer needs. Whether it’s for specialized formulations, extended-release capsules, or capsules with unique coatings, these advancements allow for greater customization, helping manufacturers meet a wide range of market demands.

Quality control is a crucial aspect of soft capsule encapsulation. Each capsule produced must meet strict standards regarding size, fill weight, and seal integrity. Continuous quality control checks are implemented at every stage of production to ensure that soft capsules deliver accurate and consistent results. This process guarantees that every capsule contains the correct dosage and that it is suitable for safe consumption.

There are several key measures used to ensure the quality of soft capsules:

● Ribbon Thickness: Ensures that the gelatin shell is consistently thick across all capsules, maintaining uniformity.

● Fill Weight Accuracy: Verifies that each capsule contains the correct amount of active ingredient, ensuring consistency in dosage.

● Seal Integrity: Ensures that each capsule is properly sealed and leak-proof, preventing contamination or loss of content.

● Dissolution Rate: Tests whether the capsule dissolves at the correct rate, ensuring that the active ingredients are released efficiently and effectively when consumed.

Quality Control Measure | Purpose |

Ribbon Thickness | Ensures uniform shell thickness across all capsules. |

Fill Weight Accuracy | Ensures each capsule contains the correct amount of fill material. |

Seal Integrity | Ensures the capsules are securely sealed to prevent leakage. |

Dissolution Rate | Verifies that the capsule dissolves at the correct rate to release the active ingredients effectively. |

Soft capsule production encounters a few common challenges that can affect the quality and efficiency of the final product. These include inconsistent fill material distribution, improper sealing, and variations in gelatin ribbon thickness. For instance, uneven distribution of the fill material may lead to capsules with varying dosage amounts. Similarly, improper sealing can cause leaks, affecting both product quality and shelf life. Variations in the gelatin ribbon thickness can result in capsules that are either too thin or too thick, leading to structural weaknesses.

These issues can often be resolved by adjusting the settings of the soft capsule encapsulator. For example, monitoring and adjusting the viscosity of the fill material ensures even distribution. Performing regular machine calibrations helps maintain uniform capsule formation. Additionally, ensuring proper temperature control during the encapsulation process can improve the consistency of the gelatin ribbons, ensuring optimal shell thickness.

Maintaining smooth and efficient operation of soft capsule encapsulation machines is critical for continuous, high-quality production. Regular maintenance and troubleshooting are key to identifying and fixing issues early. For example, wear and tear on the machine components can lead to misalignment or malfunctioning, resulting in defective capsules. Routine inspections help detect potential problems before they escalate, minimizing downtime.

By implementing a structured maintenance schedule and troubleshooting process, operators can ensure that the machinery is performing at its best, delivering consistently high-quality softgel capsules. This proactive approach not only reduces production interruptions but also ensures that the product meets the highest standards of quality and reliability.

The soft capsule encapsulator is a key machine for producing high-quality softgel capsules. By using advanced methods like rotary die encapsulation, two-phase encapsulation, and temperature control, manufacturers can meet the growing needs of the pharmaceutical and nutraceutical industries. As technology evolves, innovations in automation, AI, and eco-friendly solutions will enhance production efficiency, quality, and customization. Sinagel offers cutting-edge products that provide value through improved soft capsule encapsulation processes, meeting industry demands effectively.

A: Soft capsule encapsulation is the process of enclosing liquids or semi-solids inside a gelatin shell. This method ensures precise dosing and better bioavailability.

A: In the rotary die method, two gelatin ribbons are pressed together by rotating dies to form capsules. It’s a high-speed, precise method ideal for mass production.

A: Temperature control ensures proper gelatin viscosity, resulting in uniform capsules and effective sealing. It is essential for high-quality soft capsules.

A: Gelatin-free encapsulation offers plant-based alternatives, catering to vegan and halal requirements. It may require more precise temperature control but is gaining popularity.